Millers Falls Company: 1910-1920

Edward Stoughton’s presidency

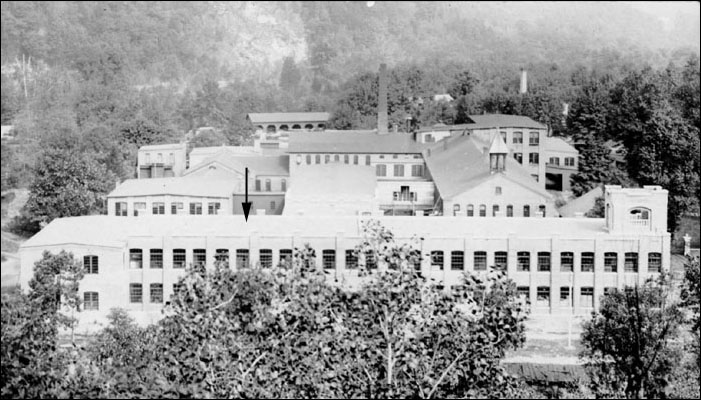

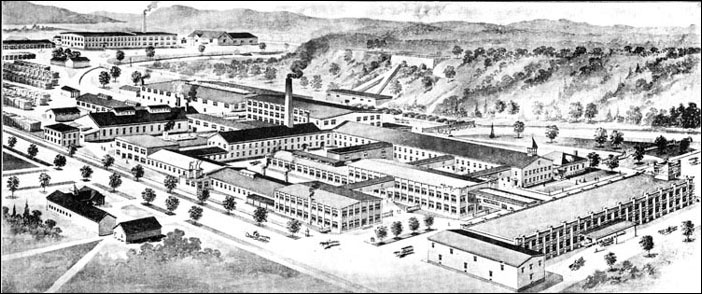

Under Edward P. Stoughton, the Millers Falls Company’s twenty-year cycle of plant expansion came to a close. By 1912, the company had completed what would be one of the last of the major construction projects at its site in Millers Falls.(1) The project, a building designed to accommodate finished goods storage, the shipping department, and areas for boxing and crating, is marked with an arrow in the above photo. A person familiar with this view of the plant might have found it difficult to reconcile the reality of the photograph with the fantasy that graced the front pages of the company’s 1912 catalog (see below). In all fairness, the wooded and hilly terrain surrounding the plant made it difficult to get a flattering photograph, and the new building, a formidable visual barrier, compounded the problem. Still, company management must have been delighted with the way the artist managed to turn a scattershot collection of mismatched buildings into the well-organized, spacious marvel of modern manufacturing pictured here.

Business was booming. According to a promotional bit in the September 1912 issue of the magazine Western New England, the new building added 50,000 square feet of floor space to the plant, and the number of company employees had grown to 500. It also reported, “... the single item of fancy cocobolo wood, imported to be turned into the handles used upon the tools, amounts yearly to several hundred tons.” A photo of the new building’s front entrance and a view of the company’s Automatics Room appear in a two-page advertisement in the same issue.(2)

On May 7, 1912, the United States Patent Office registered the Millers Falls Company's star trademark. In use since 1882 or 1883, the five-pointed star had been used to promote hack saw blades and drill chucks for decades. It began appearing on catalog covers in the early 1900s, and in 1910, covers depicting the star inside a circular band containing the words “Millers Falls Company - Toolmakers” were introduced. In 1914, the trademark was altered yet again, with the star reduced in size and positioned beneath a larger inverted isosceles trapezoid featuring the words “Millers Falls Tools.” This later version of the trademark was registered the following year.(3)

Stoughton’s background in sales may have been responsible for the unprecedented expansion in the number of products sold by the company in the decade between 1910 and 1920. The buildup is interesting in that it was not so much an increase in the types of tools available (a list that ran from angular bit stocks to wrenches) as it was an increase in the number of models produced. An extreme case in point is the company’s bit brace, a tool available in more variations than any other sold by the company. The company boasted it offered the most complete line in the marketplace—254 different braces. Many of the braces varied only slightly from one another and differences could be as small as the presence or absence of finish on the metallic or wooden parts. The number of variants on what is, after all, a simple tool was staggering, and not all of the available braces were added to the catalog. The proliferation of nearly similar tools seems an odd way in which to increase demand, and by the end of the decade, the strategy had fallen from favor. Considering that in addition to its braces, the firm marketed seventy-five different hand and breast drills; push drills; bench drills; boring machines, and auger handles, the Millers Falls Company may well have been the era’s leading manufacturer of boring and drilling tools.(4)

War and revolution

From the time that Edward Stoughton first joined the company as sales representative, Millers Falls had been remarkably successful in selling its tools overseas. The success of Stoughton’s marketing efforts had firmly established the brand in the European and Australian markets; sales to Asia and Latin America were commonplace. In 1914, thirty-six percent of all Millers Falls sales were made to international buyers. With the onset of the First World War, this blessing became a curse. Orders from England, France, Germany, and Russia almost disappeared; economic blockades and attacks on merchant vessels turned shipping into a nightmare. The effect on the Millers Falls Company was profound, and for a time, no dividends were paid to its shareholders. Halfway through the war, the company found a way to circumvent the embargoes, and the situation improved. International sales would represent nearly a third of the firm’s total through the mid-1960s.(5)

Perhaps the unluckiest Millers Falls salesman to be caught up in the era’s political intrigues was E.R. Wilner. Wilner, employed as the firm’s representative to Russia, was in the country at the time of the Bolshevik Revolution. Uninterested in politics, he assumed he would be able to continue selling tools under the new regime as he had under the old. The Bolsheviks, however, angered by the failure of the United States to recognize the new government’s legitimacy, refused to allow Wilner to leave the country and forced him to work for 4,800 rubles per month and a half-pound of rye bread per day. Wilner endured for two years before slipping away in October 1920, and walking eight miles to the border with Finland. There, he was robbed by Finnish guards and sent back to Soviet Russia. Picked up by Russian soldiers under orders to shoot him, Wilner was spared as their commander was away and was marched off to another post where his fate was to be decided. While in transit, he bribed his escorts with money that the Finns had missed and was allowed to return to the border. This time, he managed to get by the Finnish patrols and walk fifteen miles to a railway station. On his return home, a grateful Wilner would refer to the United States, without the slightest trace of irony, as “God’s country.”(6)

The Ford Auger Bit Company

In 1916, the Millers Falls Company took advantage of an opportunity to “purchase outright the stock, machinery, good will and any other assets” of the Ford Auger Bit Company of Holyoke, Massachusetts.(7) Although Millers Falls had been selling augers for decades, the purchase marked its first foray into the actual manufacture of the product. Ford Auger Bit had established a solid reputation based on its manufacture of Ellsworth Ford’s 1891 design for an improved, single-twist auger bit. The firm’s single twist, single lip models cut aggressively, provided good chip clearance, and were favored by many workers for use in basic carpentry. Although single lip bits do not produce the clean, well-defined hole of the double lip varieties, they were marketed as being faster cutting, operating with less friction, and especially useful in end grain and green, wet or knotty wood. Since Ford Auger Bit was also making single-twist, double-lip and solid-center bits at the time of its purchase, the Millers Falls Company had no trouble including a full array of augers in its 1917 catalog. Of special interest is the “Hummer bit,” a single-lip bit designed for fast work in softwoods. The Hummer was capable of boring through inch-thick pine stock in six rotations—twice as fast as a typical single-lip Ford bit and three times as fast as a cabinetmaker’s double-lip model.

In 1916, the Millers Falls Company took advantage of an opportunity to “purchase outright the stock, machinery, good will and any other assets” of the Ford Auger Bit Company of Holyoke, Massachusetts.(7) Although Millers Falls had been selling augers for decades, the purchase marked its first foray into the actual manufacture of the product. Ford Auger Bit had established a solid reputation based on its manufacture of Ellsworth Ford’s 1891 design for an improved, single-twist auger bit. The firm’s single twist, single lip models cut aggressively, provided good chip clearance, and were favored by many workers for use in basic carpentry. Although single lip bits do not produce the clean, well-defined hole of the double lip varieties, they were marketed as being faster cutting, operating with less friction, and especially useful in end grain and green, wet or knotty wood. Since Ford Auger Bit was also making single-twist, double-lip and solid-center bits at the time of its purchase, the Millers Falls Company had no trouble including a full array of augers in its 1917 catalog. Of special interest is the “Hummer bit,” a single-lip bit designed for fast work in softwoods. The Hummer was capable of boring through inch-thick pine stock in six rotations—twice as fast as a typical single-lip Ford bit and three times as fast as a cabinetmaker’s double-lip model.

In addition to offering four variations on standard-sized carpenter’s bits, the company sold machine bits, car bits, and ship augers. Custom orders were also taken. Certainly the most interesting of these was the bit designed to drill through the timbers used in constructing the locks of the Panama Canal. At the time, the Panamanian auger—a monster boring device—was considered to be the longest auger bit in the world. The company continued to manufacture auger bits at its Millers Falls plant until 1946 when it sold the equipment to the Snell Manufacturing Company.(8)

Real estate and retirement

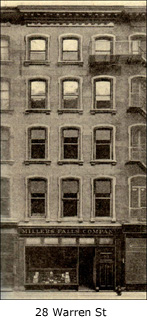

In November 1919, after twenty years of renting, the Millers Falls Company purchased the building housing its New York office. The structure consisted of five floors and two basements and was located at 28 Warren Street, in the heart of the wholesale hardware district. An extensive renovation program was undertaken shortly after purchase, and the company would soon proudly report that it occupied the entire ground floor and basements and that the upper stories were rented to “high class firms.” The front half of the first floor of the Warren Street building served as a showroom for a complete display of Millers Falls tools while the rear portion was reserved for the firm’s export offices. The company’s space needs would have been larger had the domestic sales office not been moved to Millers Falls earlier in the decade. The Warren Street address would serve as Millers Falls’ New York presence for another four decades.

In November 1919, after twenty years of renting, the Millers Falls Company purchased the building housing its New York office. The structure consisted of five floors and two basements and was located at 28 Warren Street, in the heart of the wholesale hardware district. An extensive renovation program was undertaken shortly after purchase, and the company would soon proudly report that it occupied the entire ground floor and basements and that the upper stories were rented to “high class firms.” The front half of the first floor of the Warren Street building served as a showroom for a complete display of Millers Falls tools while the rear portion was reserved for the firm’s export offices. The company’s space needs would have been larger had the domestic sales office not been moved to Millers Falls earlier in the decade. The Warren Street address would serve as Millers Falls’ New York presence for another four decades.

In 1920, Edward P. Stoughton stepped down as president of the Millers Falls Company to become chairman of the board. He had been with the concern since the opening of the New York office some fifty-two years earlier and was the last of the first-generation executives. Charles H. Amidon left the company to establish his own business in 1870; Henry L. Pratt died in 1900; Levi J. Gunn retired in 1910 and passed away in 1916; George E. Rogers died in 1915. A New Yorker to the core, Edward Stoughton’s affiliation with the company ensured he had the means to maintain a residence with a prestigious Fifth Avenue address and to continue his European travels in later life. He died October 3, 1938, aboard the Queen Mary, on a return trip from London, as the luxury ocean liner was approaching the dock. A week earlier, he and his wife had celebrated his ninety-second birthday.(9)

Illustration credits

- Photo of Millers Falls factory: Undated photo in author’s possession.

- Drawing of factory: Catalogue No. 32 of Millers Falls Company. New York: Millers Falls Company, [no date, but 1912].

- Ford Auger Bit Co: Cover of undated catalog in author’s possession.

- Linked images of new front entrance and automatic room: “Millers Falls Co.” Western New England, September 1912.

- Linked images of Ford Auger bits: Catalog No. L. Millers Falls, Mass.: Millers Falls Co., 1917.

- Linked image of world’s longest auger bit: Courtesy of Greenfield Recorder.

References

- Not including a boiler building added in the late 1940s.

- “Millers Falls Co.” Western New England, September 1912, p. 252. The illustrations are on p. xxvi-xxvii.

- The United States Patent Office registration number for the star trademark, No. 86,431; for the trapezoid and star, No. 110,863.

- Statistics on number of bit braces and drills: “The Millers Falls Co.” Hardware Dealers Magazine, January 1915, v. 43, no. 253, p. 113.

- Paul Jenkins. The Conservative Rebel: a Social History of Greenfield, Massachusetts. Greenfield, Mass.: Town of Greenfield, 1982. p. 189.

- “Salesman Finds Russia Unfriendly to Visitors.” A Century of Experience: Millers Falls Company. Greenfield, Mass.: Greenfield Record, Gazette and Courier, August 13, 1968. unpaged.

- Catalog No. L. Millers Falls, Mass.: Millers Falls Co., 1917. p. 35.

- On the largest auger bit: “Panamanian Auger.” A Century of Experience: Millers Falls Company. Greenfield, Mass.: Greenfield Record, Gazette and Courier, August 13, 1968, unpaged. The end of auger bit production: “Millers Falls is Name Famous in World of Industry.” Montague 200th Anniversary Edition: Greenfield Recorder-Gazette. (Greenfield, Mass.) June 4, 1954. p. D-13.

- Stoughton’s obituary: New York Times (New York) October 4, 1939, p. 25.