The Bit Players

This page includes information on some of the smaller players in the history of American auger bit manufacture.

Bassett, David

The Great Patent Office Fire of 1836 destroyed the documentation for the March 18, 1829, screw-auger patent issued to forty-six-year-old blacksmith David Bassett of Derby, Connecticut. Though office staff found mention of the award in surviving lists of issued patents, Basset failed to submit the original text and artwork—or certified copies—to the Office's project to re-create what was lost. His missing patent was simply assigned a reference number (5043X) to be used in the event that the original documentation came to light. Fortunately, the Franklin Institute, a Philadelphia-based research institution, published a summary of the award in its journal shortly after issue.(1) The patent covered the polishing of screw augers, and the summary reads:

This patent is taken for the manufacture, and not for the machinery employed. The ordinary screw auger is to be ground true, and polished throughout, by means of stones and buffs, in the way well known to workmen. The patentee thus states his claim.

"What I claim as new in this invention, is the auger thus made by me, whether the brightening, smoothing, or polishing, be performed by the means aforesaid, or by any other means producing the same effect."

The advantages stated to result from polishing, are the lessened liability to corrosion, and the greater ease of working, from the facility with which the chip is delivered.

In 1831, David Bassett purchased the water power right on Beaver Brook, a small tributary of the Naugatuck River in an area of Derby now known as Ansonia. Shortly afterward, he built a dam and began making augers at the site.(2) Whether his augers were the brightly polished tools described in his 1829 patent remains a matter of speculation since the accumulated dirt and oxidation of nearly two centuries would have done much to destroy the original surfaces of surviving examples. The tools he produced were stamped either "D. BASSET" or "D. BASSETT".

In 1836, David Bassett relocated to a raceway on the Housatonic River in an area of Derby known as Birmingham where he associated with Eleazer Peck and expanded production.(3) Their thriving partnership is the likely source of augers marked "D. BASSETT & CO." Peck left the operation in the mid-1840s, and Bassett brought his eldest son, Robert N. Bassett, into the business.(4) The stamped their output "D. BASSETT & SON". Sometime before 1856, David Bassett retired from active participation in the enterprise, leaving the operation in the hands of his son Robert, who soon added galvanized pump chains to the product line. Though the factory continued to make augers for a time, their manufacture was soon de-emphasized. By 1859 the company's production had shifted to metallic wires for hoop skirts and steel parts for corsets

David Bassett also sold coal, a logical sideline for someone operating a forge. His second son, Charles Lewis, worked in his father's auger shop for a time and later as a clerk in the family's coal business. Shortly before retiring from his auger business, David Bassett was appointed a deacon in his Congregational Church and was thereafter referred to as Deacon David Bassett. He died in 1872 at the age of eighty-three.

Illustration credit

- D. Basset stamp: author's photo.

References:

- “American Patents: List of American Patents Granted in March 1829.” Journal of the Franklin Institute, new series, v. 3, 1829. p. 416.

- Samuel Cutter and Ambrose Beardsley. "Further Sketches" in: The History of the Old Town of Derby, Connecticut, 1642-1800. Springfield, Mass. : Springfield Printing Company, unnumbered page 825. Not all copies of the book have this page. The copy at the University of Virginia does.

- Rockey, J. L., ed. History of New Haven County. vol. 2. New York : W. W. Preston, 1892. p. 390.

- New-England Mercantile Union Business Directory ... New York : Pratt & Co., 1849. p. 285.

Bisbee, Daniel

Daniel Bisbee, Sr., (ca. 1774-1852) was one of the early augermakers in Kingston, Massachussett, and likely apprenticed with the area's pioneering augermaker, Seth Washburn. Bisbee built a dam and set up shop on Trout Brook (originally Furnace Brook), a tributary of the Jones River in 1810. The Kingston area had a rich history of ironworking going back at least to the mid-1700s, and the stream owed its original name to the presence of an early forge or blast furnace. Bisbee made augers at the site until 1844 when he sold out to Thomas Russell.(1)

Mentions of Bisbee's business are hard to find. He displayed his "screw augers" at the First Exhibition and Fair of the Massachusetts Charitable Mechanics Association in Boston in 1839.(2) The federal census of 1850 lists him as 74 years old (an error), still living in Kingston, and working as a "smithwright," an early term for a blacksmith. The same census lists his son, Daniel jr., as a nailer, an early term for a nail maker.

His augers are stamped "D.BISBE" or D. "BISBEE".

- Welker, Peter, et al., "Generations of Augermakers in Kingston Massachusetts." Chronicle of the Early American Industries Association. v.53, no. 3 (September 2000), p. 120.

- First Exhibition and Fair of the Massachusetts Charitable Mechanics Association. Boston : Dutton and Wentworth, 1837. p. 67.

Chester Mfg. Co.

Located on the south fork of Patterson Brook in Chester, Connecticut, the Chester Manufacturing Company was active between 1884 and 1919.(1) Most surviving auger bits are of the double-spur variety. A contemporary resource observes:

The first factory on the south stream is the bitt factory of C. L. Griswold, now occupied by the Chester Manufacturing Company, consisting of Edwin G. Smith, John H. Bailey, and Charles E. Wright, who manufacture auger bitts, corkscrews, reamers, etc. The factory is on the site of a forge built about the year 1816 and occupied by Abel Snow in the forging of ship anchors. About 1838, the building was used for the manufacture of carriage springs, later by C. L. Griswold & Co. for the manufacture of bitts, and by the present owners for the same business.(2)

By March of 1893, American augermakers were producing so many standard augers and bits that they had become a commodity. A soft economy only compounded the problem. A group of ten augermakers responded by forming the American Auger and Bit Association, an organization whose primary purpose was to set prices for various categories of augers, a practice sometimes referred to as price fixing. The Chester Manufacturing Company became a charter member. Notable among the non-participants were the Irwin Auger Bit Company whose unique designs were protected by patent, and the Russell Jennings Mfg. Company whose bits commanded a premium. The organization remained active for some dozen years.(3)

References:

- Nelson, Robert E., ed. Dictionary of American Toolmakers. Early American Industries Association, 1999. p. 164.

- Silliman, Samuel C. “Town of Chester,” in The History of Middlesex County, Connecticut: with Sketches of its Prominent Men. New York : J. H. Beers & Co., 1884. p. 222.

- "Augers and Bits." The Iron Age. (March 16, 1893). p. 635.

Conard

The Conard family manufactured augers and bits in Montgomery County, Pennsylvania from ca. 1815 to 1904. The family patriarch, John Conard, apprenticed with iron-master James Wood at Watson's Ford (today's Conshohocken). In 1805 he returned to his home in Whitpain Township and took up residence on an undeveloped part of what had been his father's farm. There he cleared the land and built a house, barn, and log blacksmith shop.

The Conard family manufactured augers and bits in Montgomery County, Pennsylvania from ca. 1815 to 1904. The family patriarch, John Conard, apprenticed with iron-master James Wood at Watson's Ford (today's Conshohocken). In 1805 he returned to his home in Whitpain Township and took up residence on an undeveloped part of what had been his father's farm. There he cleared the land and built a house, barn, and log blacksmith shop.

Though John Conard is one of a half-dozen individuals credited with developing the "screw auger," his relatively late working dates preclude the possibility.(1) Three of John Conard's sons became augermakers: Albert, Isaac, and Lewis. A fourth son, Joseph P., learned the trade in his father's shop but left it behind at age twenty to go into farming.(2)

In 1846, Albert Conard was working at an auger shop in Exeter (Bucks County) when the business was liquidated. Seeing an opportunity, he purchased some of the operation's equipment and set up shop a few miles from Fort Washington in an existing mill on Sandy Run. His brother Isaac joined him the first year, and a decade later, the two became partners in the firm of A. & I. Conard. A third brother, Lewis worked for them for a time. Lewis, convinced that the traditional spelling of the family name was erroneous, changed his surname to Conrad.(3)

In 1846, Albert Conard was working at an auger shop in Exeter (Bucks County) when the business was liquidated. Seeing an opportunity, he purchased some of the operation's equipment and set up shop a few miles from Fort Washington in an existing mill on Sandy Run. His brother Isaac joined him the first year, and a decade later, the two became partners in the firm of A. & I. Conard. A third brother, Lewis worked for them for a time. Lewis, convinced that the traditional spelling of the family name was erroneous, changed his surname to Conrad.(3)

In 1871 a hardware store placed an advertisement in the Lansdale Reporter offering customers discounts on both "Conard's and Conrad's screw augers and bitts."(4) Though Lewis Conrad became a schoolteacher in later life, the text of the ad suggests that at some point, he operated an auger business independently of his brothers.

Albert Conard was at his forge making augers until the age of eighty-four. Most surviving examples of Conard family auger bits are of the double-spur variety. These are typically stem-marked "A. & I. CONARD" or are stamped on the tang with the single word "CONARD". Nut augers featuring scotch-lip heads and marked "CONRAD", rather than Conard, are also known.

Illustration credits

- Isaac and Lewis Conard portraits: http://conardfamilyhistory.com/part2.php (viewed 4/14/2023)

References:

- Bean, Theodore W., ed. History of Montgomery County, Pennsylvania. Philadelphia : Everts & Peck, 1884. p 1142, 1143, 1181.

- John and Sarah Childs Conard and their Descendants, Part 2. [s. l. : s.n.], 1939. http://conardfamilyhistory.com/part2.php (viewed 4/14/2023)

- "Death's Harvest: Albert Conard, of Fort Washington Expires." The Ambler Gazette (Lansdale, Pennsylvania). June 9, 1904. p. 4.

- "The North Wales Hardware, Iron and Stove Store." The Lansdale Reporter (Lansdale, Pennsylvania). June 22, 1871. p.3.

Conrad

See: Conard

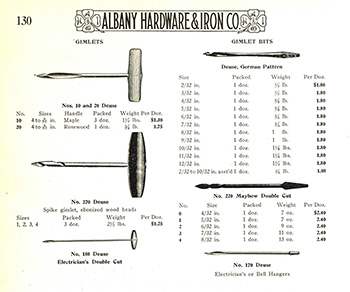

Deuse

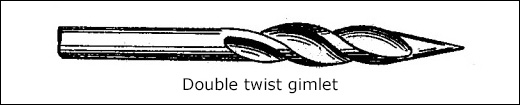

Three generations of the Deuse family made auger bits, gimlets, screwdrivers, and punches on the north branch of Pattaconk Brook in Chester, Connecticut between 1867 and 1966. The original firm, Deuse & Brother was founded by Simeon and Amos H. Deuse in 1867. When Simeon left Chester for Hartford in 1872, Amos bought the land and waterpower privilege. A third brother, James Smith Deuse, bought into the operation, and in 1880 the business became "A. H. & J. S. DEUSE".(1)

The same year Amos and James Deuse were issued United States Letters Patent No. 224,156 for a die to manufacture double-twist gimlets. Few, if any, of the Deuse operation's gimlets were stamped with a manufacturer identification. A marked example of a Deuse double-twist gimlet has yet to turn up.

The brothers' factory burned to the ground on April 28, 1898. Deep Hollow, the site of the structure, was somewhat isolated, so no one knew about the fire until the next day when workmen showed up and found the structure reduced to ashes. The office and packing room survived the fire, but Amos Deuse left the operation, leaving James S. Deuse as proprietor of the business. J. S. Deuse built a 30 x 90-foot two-story factory and attached it to the older buildings. Amos H. Deuse left the operation at this time and his brother James became the operation's sole proprietor.

To all appearances, James Smith Deuse was a respectable man serving as a representative to the Connecticut General Assembly for the 1897-98 session and as president of the Chester Savings banks from 1916 to 1928. His life, however, was not without scandal. In 1894 he was charged with the assault of Mrs. Ellen Dickenson at a family gathering.

The claim is that when Mrs. Dickenson entered the house some of the men present were having a quarrel and that Mr. Deuse struck her on the back and seizing her by the neck and arm, pushed her out of doors. Charles B. Davis testified to seeing Deuse strike Mrs. Dickenson and said it caused a swelling on her shoulder as large as a saucer. Two daughters testified to dressing the wound. The defense claimed no blows were given and that Deuse placed his hand on her shoulder, turned her around, and told her to leave.(2)

Though the outcome of the trial is unknown, the scandal was nothing compared to the fuss his son's marital problems created in 1900. Burton Deuse worked for his father as plant superintendent and bookkeeper. A married man, Burton unexpectedly ran off with his wife's sister, a lass of eighteen, leaving his toddler son and infant daughter behind. The couple fled to Galveston, Texas, and then to New York. Sadly, a lifetime of undying love was not in their future. The young lady returned home five weeks later, a sadder, but wiser woman.(3) An unpopular Burton Deuse did not return to Chester but remained in New York City. His brother Edson became increasingly involved in the operation of the company factory and when James Smith Deuse passed away in 1937, the firm became the E. W. Deuse Company. The business folded in 1966.

Illustration credits

- Double twist gimlet bit: United States Letters Patent No. 224,156.

- Deuse gimlets: [Catalog tear sheet]. Albany, New York : Albany Iron and Hardware Company, 1927. p. 130. Available: https://archive.org/details/js-deuse-albany-hardware-1927/mode/1up (viewed March 21 2023).

References

- Silliman, Kate. Kate Silliman's Chester Scrapbook. Chester, Connecticut : Chester Historical Society, 1986. p. 143.

- "Middletown." Hartford Courant (Hartford, Connecticut). April 5, 1894. p. 8.

- "Sensation in Chester." Hartford Courant (Hartford, Connecticut), June 22, 1900. p. 1; "Stella Morse Returns." Hartford Courant (Hartford, Connecticut), July 24, 1900. p. 3

Essex Manufacturing Company

Catalogs of Sargent & Company of New Haven, Connecticut, indicate the business sold auger bits stamped Essex Mfg. Co. in 1910 and 1911. Sets of the bits were put up in wooden American case boxes. Several firms bore the name Essex Manufacturing Company in the late 19th and early 20th century United States. A likely candidate for auger production has yet to be found.

French, Raymond

Note: Raymond French was not closely related to fellow Seymour augermaker Walter French.

Raymond French was nine years old at the time of his father's untimely death in 1814. At an "early age," he was apprenticed to local blacksmith Isaac Kinney.(1) He may have been twelve to thirteen years old at the time, a typical age for binding a lad to his master, though the death of his father raises the possibility he may have been as young as ten.

At the end of his apprenticeship, Raymond French went to work in a nearby auger shop where he developed a reputation as a proficient toolmaker. In 1828, at the age of twenty-six, he left Seymour and moved to the Caribbean island of Trinidad where he worked for the British government installing and maintaining machinery for making sugar cane. He returned in 1834 and partnered with John C. Wheeler in an augermaking enterprise on Bladen's Brook in a neighborhood then known as Blueville. That year, he was awarded the first of his two auger-related patents.(2) A summary of the 1834 patent in the Journal of the Franklin Institute notes:

This is said to be an improvement on screw, pump, and spur augers, and consists in giving to the plates which are to be twisted, a longitudinal, concave surface, so that the plate, as well as the pod, when twisted, shall be thinner at the centre than at the edges. ... The advantage derived from this construction is said to be, that it gives to the spiral cavities of the pod, when twisted, a greater capacity towards the inner surface, and more perfectly envelopes the core, or chips, within a metallic surface, in their passage from the bottom to the top of the hole while boring, by which they are caused to rise and flow off more freely and rapidly.(3)

French became sole owner of the business in 1837. Two years later, he and Hiram Upson bought two parcels of real estate from John C. heeler, French’s former partner. The property included a machine shop built by Newell Johnson in 1832 where the men began manufacturing augers.(4) Their partnership is the source of the rarely seen augers stamped "FRENCH & UPSON". When fire destroyed the shop on July 1, 1841 work on a replacement began almost immediately. The disaster may have had something to do with Upson leaving the business and Raymond French's decision to associate with John W. and Timothy Dwight, jr. Dwight was no stranger to augermaking. In 1837, he built a shop at the mouth of the Little River, a tributary of the Naugatuck on the bank opposite of Blueville. His business, T. Dwight Jr. and Company, manufactured augers, chisels, and plane irons. His augers won a silver medal at the 1839 fair of the American Institute of New York City.(5) His business was still listed in Price & Lee's New Haven Directory as late as 1842.

In 1843 French patented a double twist auger with a single cutting lip with one hollow deeper than the other. The deeper hollow was connected to the cutting lip. It is not known if the auger made it into production. According to French:

The superiority of this auger thus made consists in this, that it is stronger, less liable to to spring or bend, and more durable than the single twist auger, and also in boring more rapidly, and making a straighter hole, than the common double twist.(6)

The initial name for the French/Dwight collaboration was Raymond French & Company. The operation stamped its augers "RAYMOND FRENCH & CO.". The business did so well that the principals were soon looking to expand. Needing extra space, they installed machinery in a second shop at the mouth of the Little River while Raymond French scouted a location for a new dam near Kinneytown, a few miles downstream from Seymour. Securing the property he needed, French went to work on the dam immediately. Unfortunately, he began construction before he had a firm title to all the land needed to maintain exclusive rights to the water power. Though he prevailed in the end, Raymond French sold the completed dam that same year (1844) without moving Raymond French & Company to the site.

When Raymond French & Company reorganized to become Dwight & French in 1845, the operation sold its Blueville shop and bought a parcel of land and a portion of the power generated by the Rimmon Falls (Tingue) dam. They purchased these from the Humphreysville Manufacturing Company, a cloth and paper manufacturer established in 1831. The partners initially set up shop in a wooden-frame building on a canal created by the Tingue Dam. A fire destroyed the shop in 1849, and the company built a "large brick mill and fitted it up with machinery for the manufacture of augers and bits, plane irons, chisels, and drawing knives."(7) The investors changed the name of the business to Dwights, French & Company that year, indicating that Timothy Dwight's brother John had taken a substantial position in the company.

In addition to manufacturing augers, plane irons, and the like, Dwights and French began making railroad cars. In 1852, Dwights & French split into two parts: the American Car Company which focused on the railway side of the business, and a re-organized Humphreysville Manufacturing Company which made tools.(8) French, who had a controlling interest in Humphreysville Manufacturing, served as plant superintendent (and for a time as president) until 1870. At that point, he sold out, and a group headed by Norman Sperry bought the entirety of the business, continuing to operate it as the Humphreysville Manufacturing Company.

Unwilling to completely retire, French went into the business of manufacturing "plain and steel-plated" ox shoes. He passed away in February 1886 at the age of eighty-one.

Illustration credit

- 1834 patent auger: author's photos.

- Raymond French portrait: Rockey, J. L., ed. History of New Haven County. vol. 2. New York : W. W. Preston, 1892.

References

- Rockey, J. L., ed. History of New Haven County. vol. 2. New York : W. W. Preston, 1892. p. 600-601.

- United States Letters Patent No. 8491X; United States Letters Patent No. 3,181.

- “American Patents: List of American Patents Which Issued in November, 1834.” Journal of the Franklin Institute, new series, v. 15, 1835. p. 393.

- Sharpe, William C., Seymour and Vicinity: Historical Collections. Seymour Connecticut. : Record Print., 1878. p. 73.

- "Premiums Awarded at the Twelfth Annual Fair of the American Institute... " Journal of the American Institute. Vol. 4, No. 12, p. (September, 1839), p. 668.

- United States Letters Patent No. 3181.

- Campbell, Hollis A., et. al. Seymour Past and Present. Seymour, Connecticut : W.C. Sharpe, 1902. p. 161.

- Rockey, J. L., ed., p. 601.

French, Walter - Wales - Warren

Note: Walter French and his sons were not closely related to fellow Seymour augermaker Raymond French.

Note: Walter French and his sons were not closely related to fellow Seymour augermaker Raymond French.

In 1810, Walter French moved from Mansfield, Connecticut, to Humphreysville, a hamlet six miles above the mouth of the Naugatuck River. There he went to work in the blacksmith shop of Ira Smith, a veteran of the War of 1812. Smith's was a small, landlocked shop located a half mile from the Rimmons Falls dam (now referred to as the Tingue Dam). Walter French's considerable abilities soon became apparent, and he moved from employee to Smith's business associate. Smith's death in 1822 may have been the impetus behind French's decision build a shop on a nearby tributary of the Naugatuck, the Little River and go into business for himself.(1)

Though Walter French is sometimes credited with inventing the double-twist auger, he was relatively late to the game. The first commercially viable American screw auger appeared in Pennsylvania as early as 1772. It would be more accurate to credit him with pioneering the development of the tool in his part of Connecticut. Even then, there is disagreement over French's status as the first to make the auger in the surrounding area. Some believe another local blacksmith, Jessie Hartson, did so earlier. More to the point is that Walter French believed he was the first to develop the revolutionary auger. He may have come to this conclusion following a sales trip to New York where an effusive hardware dealer told him his screw augers were the first to be sold in the city and referred to him as an honor to his country.(2)

The life of an independent businessman may not have appealed to Walter French for sometime after 1837, he went on to become the superintendent of his neighbor Clark Wooster's auger shop. He remained there until Wooster closed the shop in 1844. French then moved to Westville, eleven miles away, where he is reported to have gone into the auger business.(3) The 1850 federal census records Walter French as a laborer working in Westville. The 1860 census finds him living in New Haven's Eighth Ward with surveyor William Hartley and his wife Jane and having no occupation. Aged 79 at the time of the census, he died five years later.

Walter French took his religion seriously. In 1815, he became a licensed Methodist exhorter. Exhorters did not preach the Gospel but encouraged their friends and neighbors to live upright, moral lives. He went on to become a licensed preacher, one step short of a minister, and traveled the local circuit when needed. A contemporary remembered Walter French as a man with "a good memory and a ready utterance," who often "spoke with great power and success."(4)

At least two of Walter French's sons went into the auger business. In 1844, the year their father moved to Westville, Wales French bought the Clark Wooster shop and began making augers there with his brother Warren.(5) Their business, the source of augers stamped "W. & W. FRENCH", lasted two years, coming to an end at about the time Warren became one of the six partners to form French Swift & Co. Wales French moved to Westville and continued to make augers, stamping them "WALES FRENCH". He stuck with the auger business through at least 1857. The 1860 federal census finds him living in New Haven's second ward and working as an insurance agent.

On April 5, 1847, Warren French joined Charles Swift, Henry B. Beecher, John F. Marshall, Lemuel Bliss, and Horace Radford to form French, Swift & Company. The company's primary products were augers and bits. Their output was stamped, logically enough, "FRENCH, SWIFT & CO." Henry B. Beecher bought out his partners one at a time until 1866 when he gained control of the company and renamed it Henry B. Beecher. Warren French followed in his father's footsteps and became a licensed exhorter and preacher in the Seymour Methodist Episcopal church. One observer remembered, "Warren French was an exhorter whose exhortations went to the hearts of sinners as red-hot as the augers he twisted at his forge."(6)

Illustration credit

- Walter French portrait: Basset, Frank G. “Town of Seymour.” The Connecticut Magazine: an Illustrated Monthly. v. 66, no. 5, (July-August) 1900.

References

- Sharpe, W. C. A History of Seymour Connecticut with Biographies and Genealogies. Seymour, Connecticut : Record Print, 1879. p. 155; Rockey, J. L., ed. History of New Haven County. vol. 2. New York : W. W. Preston, 1892. p. 574.

- Campbell, Hollis A., et. al. Seymour Past and Present. Seymour, Connecticut : W.C. Sharpe, 1902. p. 158-159.

- Campbell, p. 159.

- Sharpe, History of Seymour Connecticut with Biographies ... , p. 175.

- Campbell, p. 159, again.

- Sharpe, W. C. Annals of the Methodist Episcopal Church of Seymour Connecticut. Edition of 1896. Seymour Connecticut : Record Print, 1896. p. 89.

Griswold

In 1851 Charles L. Griswold, his brother George G. Griswold, and Samuel Wright formed C. L. Griswold & Company and began manufacturing augers on the south branch of Pattaconk Brook in Chester, Connecticut. They set up shop in a collection of wood-frame buildings that had been painted red some years earlier. Locals referred to the works as the Red Factory to differentiate it from a nearby manufacturing operation known as the Yellow Factory.(1)

In 1851 Charles L. Griswold, his brother George G. Griswold, and Samuel Wright formed C. L. Griswold & Company and began manufacturing augers on the south branch of Pattaconk Brook in Chester, Connecticut. They set up shop in a collection of wood-frame buildings that had been painted red some years earlier. Locals referred to the works as the Red Factory to differentiate it from a nearby manufacturing operation known as the Yellow Factory.(1)

In 1854 George G. Griswold erected a new building near the Red Factory and began manufacturing augers. Two hundred-twenty feet long, twenty-eight feet wide, and topped with a cupola housing the factory bell, the two-story structure was anything but humble. Whether the building ever housed the operations of C. L. Griswold is hard to determine, for in the mid-1850s George Griswold organized George G. Griswold & Company and began making augers there. A peripherally related 1881 court case suggests that Charles Griswold owned the site of his brother's operation.(2) The Red Factory continued to house the operations of C. L. Griswold & Company.

While George G. Griswold & Company identified some of its output with a traditional "GEO. G. GRISWOLD & Co." mark, at times it stamped "G. G. G. & CO." on the tangs of its auger bits. At some point, Jarvis Boies (also spelled Bois) became a major investor in George Griswold's operation. His participation in the business goes far in explaining the occasional appearance of bits marked "GRISWOLD & BOIS". In 1856, George Griswold patented a method for varying the thickness of the flattened plate of an auger bit before twisting. By leaving the plate thicker in the middle, rather than on the edges, Griswold hoped to improve the strength of the bit and promote the freer passage of chips up the spiral by shunting them to the outer edge of the twist. His patent application was witnessed by his brother Charles Lee Griswold and Joshua L'Hommedieu.(3)

George G. Griswold & Company sold their 10-year-old factory to Turner, Day & Company on August 25, 1863. The principals, Sidney Turner and Edward Day, were George Griswold's sons-in-law and intended to manufacture ship augers and bolts. Turner, Day & Company's stay at the plant was a short one. On February 15, 1865, the Turner & Day operation quitclaimed the land back to C. L. Griswold and Company.(4) The Russell Jennings Company began producing augers in the factory later that year.

In May of 1865, Charles L. Griswold, still working in the Red Factory, patented a double-twist auger bit in which the cutting lips projected from the lead screw at nearly a right angle. Though much of the company's output consisted of standard double-spur bits with tangs stamped "C. L. GRISWOLD CAST STEEL", bits protected by the 1865 patent were manufactured. These patented bits the tang-stamp "C. L. GRISWOLD PAT'D MAY 30, 1865". Charles Griswold went on to secure a pair of patents for gimlet handles in 1872 and 1873. A patent for a bitstock followed in 1878, and one for a corkscrew in 1884.(5) The bit-stock may not have been manufactured.

In May of 1865, Charles L. Griswold, still working in the Red Factory, patented a double-twist auger bit in which the cutting lips projected from the lead screw at nearly a right angle. Though much of the company's output consisted of standard double-spur bits with tangs stamped "C. L. GRISWOLD CAST STEEL", bits protected by the 1865 patent were manufactured. These patented bits the tang-stamp "C. L. GRISWOLD PAT'D MAY 30, 1865". Charles Griswold went on to secure a pair of patents for gimlet handles in 1872 and 1873. A patent for a bitstock followed in 1878, and one for a corkscrew in 1884.(5) The bit-stock may not have been manufactured.

The Red factory burned on October 1, 1878, and Charles Griswold promptly began construction of a replacement. The work was finished three months later.(6) In 1884 he leased the factory to his son-in-law Edwin G. Smith and Smith's partners, John H. Bailey and Charles E. Wright. The three partners went into business as the Chester Manufacturing Company and produced auger bits, reamers, and corkscrews.

Illustration credits

- C. L. Griswold portrait: https://www.findagrave.com/memorial/31462312/charles-lee-griswold (viewed March 22, 2023)

- 1865 patent auger image: United States Letters Patent No. 14,561.

References

- Silliman, Kate. Kate Silliman's Chester Scrapbook. Chester, Connecticut : Chester Historical Society, 1986. p. 110, 146-147.

- Blatchford, Samuel. Reports of Cases Argued and Determined in the Circuit Court of the United States for the Second Circuit. Vol. 19. New York : Baker & Vorhis Company, 1883. p. 95.

- United States Letters Patent No. 14,561.

- Blatchford, p. 95-96.

- The gimlet handles: United States Letters Patent No. 133,440 and United States Letters Patent No. 143,142. The bit stock: United States Letters Patent No. 208,168. The corkscrew: United States Letters Patent No. 302,331.

Hicraft

A brand name for auger bits produced by the Midway Tool Company of Melville, Ohio. Organized by former employees of the Irwin Auger Bit Company in 1946, the factory with its two trip hammers was located some half-dozen miles from Irwin's plant in Wilmington. The business remained in Melvin until 1955 when production moved to Sabina Ohio. Boxes of its augers bits touted its "1,000 man years' experience."

Source: "New Company to Make Bits." Wilmington News-Journal (Wilmington, Ohio) January 21, 1947. p. 10.

Hudson Forge

"HUDSON FORGE CO." was a hardware trademark first used by the W. T. Grant Company in 1923. The Grant company operated a chain of variety stores situated in downtown locations. Slow to adapt to changes as American shoppers gravitated to retailers in the suburbs, the company went bankrupt in 1976.

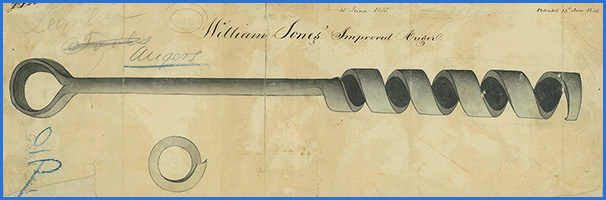

Jones, William

William Jones, of Portsmouth, Virginia, a shipbuilding hub, patented a device he referred to as a "hollow auger" on June 15, 1835. The Journal of the Franklin Institute published this description.(1)

The specification of this invention is brevity itself exemplified; it consists of the following words. "This invention is a hollow auger made so as to embrace the bolts or fastenings in ships or vessels, and to cut the wood from around them by which the plank, &c., can be removed without the delay, trouble, and expense, usually acquired by splitting them out."

In the drawing the auger is represented as twisted like the ordinary screw auger, but capable of allowing the bolt to pass within it. This must be a very useful thing, and, so far as we know, is new.

The record for the patent was lost in the Patent Office fire of 1836. The fire destroyed the documentation for the 9,947 patents issued to that date. Congress responded to the disaster by passing the Patent Act of 1837. The act declared the destroyed patents invalid unless the rights holders submitted their original documents or certified copies to the Patent Office. Upon receipt, the documents were transcribed and when possible, the Patent Office artists recreated the original artwork that accompanied the patent application.

A likely candidate for the William Jones who invented this early hollow auger is William A. Jones, a blacksmith living in Portsmouth who perished in the city's infamous yellow fever epidemic of 1855. Examples of the Jones auger have yet to be discovered.

Illustration credits

- Reconstructed Patent Office drawing of William Jones' improved auger. Drawing is undated.

References

- “American Patents: List of American Patents Granted in June 1835.” Journal of the Franklin Institute, new series, v. 17, 1836. p. 49.

Ladd — W. J. Ladd Edge Tool Company

W. J. Ladd worked for Sargent & Company of New Haven, Connecticut, from 1856 through at least 1903. Sargent Company catalogs for 1910 and 1911 contain listings for auger bits manufactured by Ladd. Sets of Ladd bits were sold in wooden American case boxes.

Leland & Co.

In 1843 John P. and Samuel J. Leland began making augers at a site on the west branch of the Little River in South Charlton, Massachusetts. The village that grew up near their factory became known as Lelandville. The men manufactured bits and augers until 1861 when they began making ramrods for the United States federal government.(1) The Lelands' business appears to have already folded when Henry Stevens of the Dudley Linen Works bought the factory in 1865. Leland augers and bits were typically the double-spur design and stamped "MFD. BY LELAND & CO." on the stem.

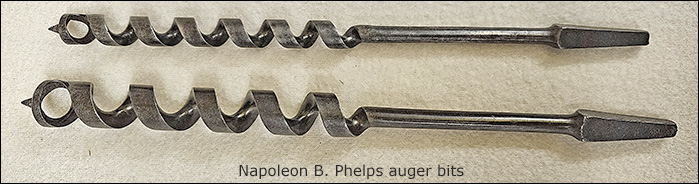

A notable exception to the company's regular production was the single-spiral auger patented by the Lelands' brother-in-law Napoleon B. Phelps on December 27, 1859.(2) Phelps attached the auger's cutting lips to the coil just above them. His intent was to reduce the breakage of a bit's cutting edge during hard use. The Phelps design did not take the world by storm. Though Phelps' patent documents claim rights to the design for both single and double spiral bits, surviving examples are of the single spiral variety. Leland & Co. stamped its Napoleon Phelps bits "LELAND & CO. PAT'D. Dec 27, 1859".

At some point, Phelps manufactured double-spur augers under his own name. The location of his factory and years of production are unknown. Examples are stamped "MFD. BY N. B. PHELPS".

Illustration credits

- Phelps auger bits: author's photo.

References

- Hurd, Duane Hamilton. History of Worcester County, Massachusetts: with Biographical Sketches ... Vol. 1 Philadelphia : J. W. Lewis & Co., 1889. p. 757.

- United States Letters Patent No. 26,612.

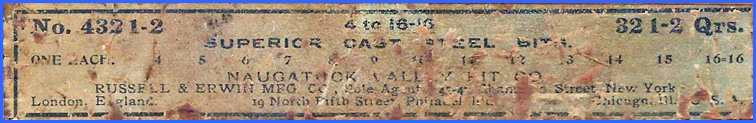

Naugatuck Valley Bit Company

Auger bits manufactured by the Naugatuck Valley Bit Company were distributed by the Russell & Erwin Mfg. Co., the company that for many years distributed the products of the James Swan Company, a major manufacturer of auger bits and chisels. There is some evidence that Naugatuck Valley bits were manufactured by the James Swan operation.

Sets of Naugatuck Valley bits were distributed in boxes patented by James Swan in 1886 and marked with the patent number (United States Letters Patent No. 337,888). Seymour, the headquarters of James Swan Company, is just seven miles from the junction of the Housatonic and Naugatuck Rivers in Derby.

Illustration credits: author's photosRockford Bit Company

The Rockford Bit Company was founded in Rockford, Illinois, in 1886 by Robert Hall Tinker and Wilton C. Smith. In late 1887 or early 1888, the company bought Ohio-based Ashtabula Auger Works. The ink was hardly dry on the papers when W. C. Smith bought Tinker's shares and became sole proprietor of the operation. In 1888 the company moved to Kokomo, Indiana. A brief article in the trade journal Iron Age noted:

W. C. Smith, secretary and treasurer of the Rockford Bit Company, Rockford, Ill., having recently purchased R. H. Tinker’s stock, has become sole proprietor. The company have lately bought the Ashtabula Bit Works, the two establishments being thus consolidated. Since then Mr. Smith has been considering the advisability of using natural gas, and in view of the advantages resulting from its use has decided to move the works from Rockford, Ill., and Ashtabula, Ohio, to Kokomo, Ind., where the company are now building factory, storerooms, office, &c. It is intimated that when the new works are completed the company will have a very convenient and well-arranged factory. The use of natural gas is referred to as enabling them to produce goods of exceptional quality. With the increased facilities thus given they will continue the manufacture on a larger scale than heretofore of their Perfection Auger Bits, special wood boring tools, machine bits, &c.(1)

Smith's choice of a location for his factory owed much to Kokomo's location in what was then referred to as the "natural gas belt." The site he chose, three-quarters of a mile from the nearest road, met with derision on the part of local historian Jackson Morrow, a surveyor who considered that Wilson had been hoodwinked by local hustlers. Though the parcel was not close to town, it consisted of pieces of three adjoining farms owned by the men showing him the property. They donated the land to Smith, likely in the hope that the new plant would increase the value of their adjacent properties. In Morrow's view, their self-interest did not compensate for the generosity of their actions. His opinion of the ethics of J. R. Hall, Wick Russell, and Garah Markland aside, Morrow provided one of the few contemporary descriptions of the Rockford Bit Company.

In 1892 Henry C. Davis and his son, Henry C., Jr., bought an interest in the factory. In 1893 they and H. A. Bruner bought in all outstanding stock. They manufacture augurs, augur bits and carpenter chisels. The present floor space is about 25,000 square feet. In 1892 the number of men employed was from thirty to forty. In 1908 the number is one hundred and fifty to one hundred and sixty, and the pay-roll is eighty thousand to one hundred thousand dollars per year. The capital stock is seventy-five thousand dollars. The officers are: H. C. Davis, president; H. A. Bruner, vice-president; H. C. Davis, Jr., treasurer; George L. Davis, secretary; George J. Costello, superintendent.(2)

By March of 1893, American augermakers were producing so many standard augers and bits that they had become a commodity. A soft economy only compounded the problem. A group of ten augermakers responded by forming the American Auger and Bit Association, an organization whose primary purpose was to set prices for various categories of augers, a practice sometimes referred to as price fixing. Rockford Bit became a charter member. Notable among the non-participants were the Irwin Auger Bit Company whose unique designs were protected by patent, and the Russell Jennings Mfg. Company whose bits commanded a premium. The organization remained active for some dozen years.(3)

Perhaps the best known of the Rockford Bit Company's bits were its "PERFECTION JENNINGS" augers. Sets of the bits were put up in wooden American case boxes. The company stamped much of its output with a single word, "ROCKFORD". Some of the company's double-spur bits bear the remarkably wordy designation ...

KOKOMO

ROCKFORD

Workers at the Rockford Bit Company went on strike in 1916. The unintended consequence of their action was that the business folded. Greenlee Brothers & Company bought the company’s assets and moved the stock and equipment to Rockford, Illinois the following year. The articles of dissolution for the Rockford Bit Company were filed on August 13, 1917, in Indiana.

Illustration credits

- Robert Hall Tinker: "Robert H. Tinker." Rockford Public Library: Tinker Swiss Cottage (Illinois Digital Archives) (viewed March 22, 2023)

- Perfection Jennings images: author's photos

References

- "Items." Iron Age. July 17, 1888. p. 68

- Morrow, Jackson. History of Howard County, Indiana. Vol. 1. Indianapolis: B. F. Bowen, [1909?]. p. 242-243.

- "Augers and Bits." The Iron Age. (March 16, 1893). p. 635.

Sanford, Nathaniel C. (N. C. Sanford & CO.)

Nathaniel C. Sanford was one of seven Connecticut men who established an augermaking enterprise in Meriden during the fall of 1826.(1) The other investors included: Julius Pratt, Erastus P. Parmelee, Fenner Bush, Howell Merriman, Edward Sanford, and Elisha A. Cowles. The bulk of the operation's output was marketed by an entity known N. C. Sanford & Company, the firm's accredited sales agent. Six months later, the company leased a factory on Harbor Brook from investor Elisha A. Cowles. Unfortunately, the small steam in West Meriden proved an unreliable source of power. In 1832, the operation bought the factory of Carter, Goodrich & Bishop, makers of bone buttons, located on the much larger Quinnipiac River.(2)

The original investors in the augermaking operation parted ways in the spring of 1833. Nathaniel C. Sanford, Julius Pratt, Erastus P. Parmelee, Howell Merriman, and Edward Sanford sold their shares in the company. A smaller group of investors composed of Elisha A. Cowles, Fenner Bush, Walter Booth, and Isaac I. Tibbals, acquired the assets of the operation and formed a new enterprise—Tibbals, Bush & Company. Tibbals & Bush took on the manufacture of N. C. Sanford & Company's product line: rakes, augers, and bits.(3) The business reorganized in 1835 and became Tibbals, Brooks & Company. The new iteration of the firm was not long-lived and went out of business about 1840.

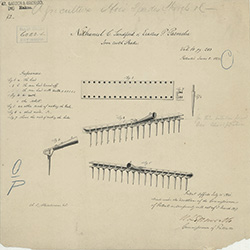

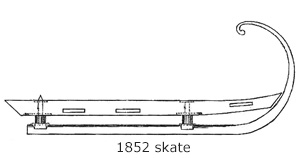

During the 1830s, the United States Patent Office issued four patents to Nathaniel C. Sanford. The first was for a curry comb. Sanford co-patented the second, an iron-tooth rake, with Erastus P. Parmelee in 1830. The third of Sanford's patents, an ice skate, and the fourth, an auger, were awarded in 1834—the year after the original, short-lived N. C. Sanford & Company broke up.(4) The drawings of the 1834 skate have disappeared, and it is not known to have been manufactured. Sanford's 1834 auger patent added a second cutting lip to Ezra L'Hommedieu's single spiral auger. (L'Hommedieu's patent expired in 1830.)

In August 1834, Isaac I. Tibbals—of Tibbals, Bush & Company—witnessed a patent application for an auger developed by Meriden resident Alfred Newton. Newton's auger was unusual in that it had three cutting lips and three channels for the clearing of wood chips. Tibbals & Brooks manufactured the design for a time, but it never caught on and examples are few.(5)

The records for the early Nathaniel Sanford and Alfred Newton patents were lost in the Patent Office fire of 1836. The fire destroyed the documentation for the 9,947 patents issued to that date. Congress responded to the disaster by passing the Patent Act of 1837. The act declared the destroyed patents invalid unless the rights holders submitted their original documents or certified copies of them to the Patent Office. Upon receipt, the documents were transcribed and when possible, the Patent Office artists recreated the original artwork that accompanied the patent application. The artwork then became the basis for the line drawings found in official Patent Office publications. The United States Congress ended the effort in 1847 when it discontinued the funding. By that time, employees had recreated 2,845 of the destroyed patents.

At some point before 1845, Nathaniel C. Sanford and Alfred Newton joined forces to become Sandford, Newton & Company. Their factory was located on the Quinnipac River a half-mile downstream from that of Tibbals, Brooks & Company. In 1845 Sanford & Newton are on record as the manufacturers of "augers, rakes, etc." worth a total of $20,000 and as employers of 28 hands.(6) When Alfred Newton, Lucius B. Smith, and Elias Sanford patented an innovative auger with a graduated twist on March 27, 1847, N. C. Sanford, Newton & Company manufactured it.(7) The inventors maintained that the wider channels at the top of the twist facilitated the passage of chips, leading to less clogging and minimizing the time required to pull the auger out of the hole to clear a blockage. The patent covered the use of the graduated twist on both single and double-twist augers.

The team that developed the graduated twist auger knew each other well. Newton, of course, was a partner in Sandford & Newton. Elias Sanford was Nathaniel Sanford's half-brother. Lucius B. Smith was raised by his maternal uncle Erastus Parmelee and learned blacksmithing from him. Erastus P. Parmelee would become a co-owner of the business when Alfred Newman died at age forty-one, two short months after co-patenting the graduated twist auger. The reorganized enterprise became Sanford, Parmelee & Company. Mentions of the business are scarce. Like its predecessor, the company manufactured bits, rakes, and skates and employed some forty hands.(8) Its augers were stamped "SANFORD, PARMELEE & CO.".

In 1849, N. C. Sanford patented an additional two augermaking ideas. The first, United States Letters Patent No. 6221, covered a methodology for producing the graduated twist auger. Shortly afterward, Sanford co-patented an augermaking machine with Erastus Parmelee's nephew, Lucius B. Smith.(9)

By 1856, the name of the business had reverted to N. C. Sanford & Company and at about this time, Erastus P. Parmelee left the area.(8) The 1860 federal census finds him living in Broadalbin (Fulton County) New York, and working for a mitten manufacturer. At the time of the 1865 New York State census, he was still living in Fulton County, working as a machinist in Johnstown.

Between 1856 and 1868, Sanford patented an auger handle and two two augers. United States Letters Patent No. 15,147 protected a handle for a ring-type auger featuring a threaded plate attached to the lower side of the ring. A bolt passing through the wooden handle engaged the threads and provided a secure, non-slip way of attaching it to the ring. Letters Patent No. 36,534 covered an auger with supplemental lips for boring through end grain. His final patent, Letters Patent No. 79,012, protected an auger with "two or more cutting lips ... of different radial distance from the axial center from the auger." As interesting as the drawing accompanying the award might be, the patent did not indicate what the advantages of such an arrangement would be. It appears none of the three patents made it into production.

During the 1850s & 60s, N. C. Sanford continued to patent and manufacture ice skates in addition to augers and bits. His designs were successful, and examples based on his 1852 patent(10) are considered nothing less than works of art. Sanford & Co. continued making augers and skates until he sold the business to Clark, Wilson & Co. shortly before the United States Civil War. The New York hardware firm that operated the enterprise as the Eagle Auger and Skate Company. Clark & Wilson sold the business to Edward H. Tracy who continued to manufacture augers and skates under his own name.

During the 1850s & 60s, N. C. Sanford continued to patent and manufacture ice skates in addition to augers and bits. His designs were successful, and examples based on his 1852 patent(10) are considered nothing less than works of art. Sanford & Co. continued making augers and skates until he sold the business to Clark, Wilson & Co. shortly before the United States Civil War. The New York hardware firm that operated the enterprise as the Eagle Auger and Skate Company. Clark & Wilson sold the business to Edward H. Tracy who continued to manufacture augers and skates under his own name.

In 1880 Tracy organized the L'Hommedieu Tool Works, an operation with a product line virtually identical to that of its predecessor. L'Hommedieu Tool was not destined for a long life. Neither was E. H. Tracy. In poor health, he was advised to get his affairs in order. Tracy responded to his doctor's recommendation by associating with C. E. Jennings and Francis B. Griffin in 1881 to incorporate his business as the L'Hommedieu Hardware Company. After Tracy's death in 1882, the surviving officers changed the business's name to Jennings & Griffin Manufacturing Company.(11)

Born in 1796 in Old Saybrook, Connecticut, Nathaniel Clark Sanford died in Bricksburgh, New Jersey, on December 11, 1877.

Illustration credits

- Reconstructed United States Patent Office drawing of rake "made under the direction of the commissioner of patents in conformity with act of 3rd March 1837." Drawing dated July 31st, 1841.

- Reconstructed Patent Office drawing of Nathaniel C. Sanford twist auger. Drawing is undated.

- Reconstructed Patent Office drawing of Newton graduated twist auger. Drawing is undated.

- Graduated twist auger: author's photo.

- 1852 ice skate: United States Letters Patent No. 9,079.

References

- Davis, Charles Henry Stanley. History of Wallingford, Conn., from its Settlement in 1670 to the Present Time. Meriden, Conn : published by the author, 1870. p. 162.

- Gillespie, Charles Bancroft (compiler). An Historic Record and Pictorial Description of the Town of Meriden, Connecticut and Men Who Have Made It. Meriden Conn. : Journal Publishing Company, 1906. p. 356.

- "Notice." Hartford Courant (Hartford, Connecticut). April 9, 1833. p. 1.

- The curry comb: United States Letters Patent No. 997X; the rake: United States Letters Patent No. 6022X; the skate: United States Letters Patent No. 8051X, the auger: United States Letters Patent No. 8350X.

- Nichols, Nick. "In Search of the Three-Lipped Auger." Chronicle of the Early American Industries Association. Vol. 59, No. 3 (September, 2006) p. 109-110.

- Gillespie, p. 306.

- United States Letters Patent No. 6305.

- Davis, p. 495.

- New England Business Directory in Which the Mercantile, Professional ... Boston : George Adams, 1856. p. 554.

- United States Letters Patent No. 9,079.

- "Mr. Tracy's Death." The Meriden Republican (Meriden, Connecticut), February 14, 1882. p. 2.

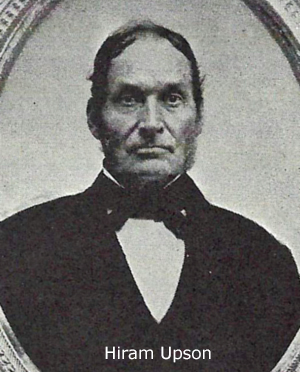

Upson, Hiram

At some point in the 1820s, Hiram Upson, a native of Wolcott, Connecticut, made the thirty-mile trip to the town of Derby to seek his fortune. Derby, located at the junction of the Naugatuck and Housatonic Rivers, was home to Walter French, an early manufacturer of double-twist augers who is sometimes credited with developing the tool. French set up shop there in 1810 in an area known as Humphreysville.

At some point in the 1820s, Hiram Upson, a native of Wolcott, Connecticut, made the thirty-mile trip to the town of Derby to seek his fortune. Derby, located at the junction of the Naugatuck and Housatonic Rivers, was home to Walter French, an early manufacturer of double-twist augers who is sometimes credited with developing the tool. French set up shop there in 1810 in an area known as Humphreysville.

Little is known of Upson’s early years in his new home but in 1839, he associated with Raymond French in an augermaking enterprise. The pair bought two pieces of real estate from John C. Wheeler, French’s former partner in an augermaking business.(1) French and Upson began manufacturing augers and bits in a former machine shop located on their property in 1832. Their business is the source of the rarely seen augers stamped "FRENCH & UPSON".

When fire destroyed the buildings located on the French & Upson Property in 1841, work on replacements began at once.(2) The event may have had something to do with Hiram Upson leaving the business and Raymond French's decision to partner with Timothy Dwight to form Raymond French & Company (later Dwight and French, later still Dwights French & Company).(3)

An 1849 village directory lists Hiram Upson as an independent business owner working in a shop on the Little River in Humphreysville.(4) Though he remained in place, his address changed the following year when the Connecticut General Assembly changed the name of the village to Seymour.

In 1852 Upson joined Horace A. Radford and Lucius Tuttle to form the Upson Manufacturing Company, an enterprise organized with a capital of $6,000. The men set up shop at the mouth of the Little River in a building originally built by Timothy Dwight, Sr. and sold by his heirs to Radford in 1837.(5) Upson Manufacturing employed some twenty hands on average, fired four forges, and operated two trip hammers.(6) The augers it produced are marked "UPSON MFG. CO." It appears that the owners dissolved the business in 1859 when H. A. Radford sold the property to Charles Douglass, and it became the site of the Douglass Manufacturing Company.

Though Upson still considered himself an auger manufacturer at the time of the 1860 federal census, corroborating evidence is unavailable. Augers marked "H. UPSON" likely originate from that period or the years before he partnered with Raymond French. Upson reported he was a farmer at the time of the 1870 census. He died in 1874.

Illustration Credits

- Hiram Upson tintype reproduction: Portrait Painting in America: the Nineteenth Century. New York : Mainstreet/Universe Press, 1977.

- H. Upson stamp: author's photo.

References

- Sharpe, William C., Seymour and Vicinity: Historical Collections. Seymour Conn. : Record Print., 1878. p. 73.

- Rockey, J. L., ed. History of New Haven County. vol. 2. New York : W. W. Preston, 1892. p. 574.

- Sharpe, p. 49.

- Sharpe, p. 79; Rockey p. 575.

- Sharpe p. 87.

- “Industrial Statistics.” The Plough, the Loom, and the Anvil. v. 8, no. 7. (January 1856) New York : [publisher not given], p. 418.

Watrous & Company

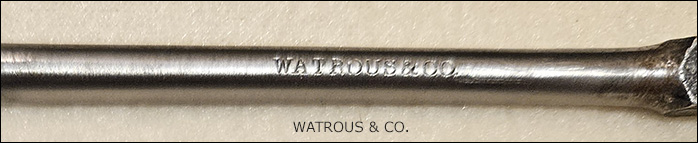

In 1832, eighteen-year-old Richard N. Watrous went to work for the L'Hommedieu brothers, well-known augermakers in his hometown, Chester, Connecticut.(1) A talented youth, he became the operation's foreman at age twenty-one, and co-patented a device for making double twist augers with Ezra L'Hommedieu in 1838.(2) At some point, Watrous assigned his rights to the augermaking machine to L'Hommedieu who had the patent reissued in 1845, a move likely prompted by Watrous's relocation to Charlestown, Ohio, the previous year. There, Watrous joined three other men from Connecticut's Chester/Deep River area—Levi B. Southworth, Ansel Shipman, and his brother Justin Watrous—in organizing Watrous & Company, an augermaking business. They set up shop some six miles east of Ravenna in an area that became known as Augerburg.

In 1857, R. N. Watrous patented an adjustable handle draw knife that allowed a user to adjust the angle of the blade to fit the task at hand.(3) Shallow cuts facilitated work with hardwoods, and deeper cuts allowed for the aggressive removal of softwood stock. Watrous & Company began making the draw knife. Eventually manufactured by both the C. E. Jennings and James Swan companies, the tool remained in production for the next half-century.

The business reorganized as Watrous, Shipman & Company when Levi Southworth left in April 1858. His was not an amicable departure. Southworth left his partners with an uncollectable promissory note for $5,193.12—a substantial sum at the time. The matter went to the Portage County, Ohio Court of Common Pleas. Its disposition remains unknown.(4) Watrous, Shipman & Company continued doing business in Augerburg, making bits, ship augers, and draw knives until the second year of the United States Civil War when the principals dissolved the business.

In 1866, after the secession of the hostilities, the Watrous brothers and Shipman relocated to Elmira, New York, where Milton V. Nobles had just organized a business for the manufacture of bit braces and specialty carpenter's tools. Shipman soon became superintendent of the plant, R. N. Watrous spearheaded the auger operation, and Justin Watrous worked in the finishing department. In addition to turning out tools under its own name, Nobles Manufacturing Company factory made augers, bits, and draw knives under the Watrous & Co. name. The operation's Watrous-branded ship augers sold especially well, garnering a worldwide reputation.

Milton V. Nobles sold his interest in his company in April 1871, and a new group of investors reorganized the business as the Elmira Nobles Manufacturing Company. Richard N. Watrous stayed on at the factory, and four months later patented an improved die for forming the lips of auger bits.(5) His idea was sound and incorporated into the production of bits manufactured by the company.(6)

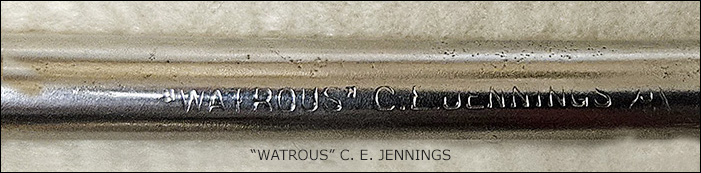

R. N. Watrous was still at his job in 1877 when the buildings and machinery were sold at auction. Soloman L. Gillet and Robert T. Turner either bought the operation or rented the plant from someone who did and formed Gillet & Co. The Gillet operation continued making Watrous-branded augers, drawknives, and bits until January 1886, when C. E. Jennings & Company rented the factory. Though a now-retired R. N. Watrous passed away the next September, C. E. Jennings & Company kept the Watrous brand alive. When fire destroyed the Elmira factory in 1887, production of Watrous brand tools moved to Meriden, Connecticut.(7) Early on, C. E. Jennings' publicity portrayed the company as an independent entity. Jennings began treating its acquisition as a brand in the early 20th century, marking the bits with the word WATROUS in quotation marks.

Illustration credits

- Watrous bit stamps: author's photos.

References

- "The Late Richard Watrous." The Democratic Press (Ravenna, Ohio) September 2, 1886. p. 3.

- United States Letters Patent No. 851 reissued as RE72.

- United States Letters Patent No. 18,887.

- "Dissolution of Copartnership." The Portage Sentinel (Ravenna, Ohio) May 20, 1858. p. 3; "Legal Notice." The Portage Sentinel (Ravenna, Ohio) July 29, 1858. p. 3.

- United States Letters Patent No. 117838.

- "Abram M. Dewitt vs. Elmira Nobles Manufacturing Company." in Reports of Cases Heard and Determined in the Supreme Court of the State of New York. Vol. 12. New York : Banks & Brothers, 1876. p. 301. D. Mason & Co.,

- Towner Ausburn. Our County and Its People: a History of the Valley and County of Chemung ... Syracuse, New York : 1892. p. 607.

Wilson, Joseph (J. Wilson)

Born in 1770, possibly in Brookfield, Massachusetts, Joseph Wilson moved to Marlborough, New Hampshire, where he worked as a blacksmith.(1) A skilled mechanic, his shop turned out augers and such agricultural implements potato hooks and hoes. The United States Patent office awarded him a patent for the improvement of the prong of a hoe September 20, 1827.(2) His house straddled the boundary line of the towns of Marlborough and Keane. He once avoided arrest by walking from the Keene piece of his home into the Marlborough part where the Keene constable had no authority to detain him. He was known to stamp his augers "J. WiLSON" with a lower case "i."

Illustration credits

- Wilson auger stamp: author's photo.

References

- Bemis Charles A. History of the Town of Marlborough, Cheshire County New Hampshire. Boston : Press of G. H. Ellis 1881. p. 699.

- Nelson, Robert E. Dictionary of American Toolmakers. [Place of publication not given] : Early American Industries Association, 1999. p. 868.