W. A. Ives/The Mephisto Auger Bit

First produced by the W. A. Ives Mfg. Company in Connecticut and later by the Mephisto Tool Company of Hudson, New York, the Mephisto auger bit has a complex and interesting history. The bit came into being in 1909, long after W. A. Ives, the company's founder, had passed from the scene. It remained in production long after the demise of the Ives Company itself. The tale of the leadup to the bit's introduction and the years that followed is one of inventiveness, disastrous fires, mismanagement, lawsuits, and a succession of no less than eight companies.

First produced by the W. A. Ives Mfg. Company in Connecticut and later by the Mephisto Tool Company of Hudson, New York, the Mephisto auger bit has a complex and interesting history. The bit came into being in 1909, long after W. A. Ives, the company's founder, had passed from the scene. It remained in production long after the demise of the Ives Company itself. The tale of the leadup to the bit's introduction and the years that followed is one of inventiveness, disastrous fires, mismanagement, lawsuits, and a succession of no less than eight companies.

A number of the eight companies had nearly identical names, a circumstance that complicates a casual reading of the W. A. Ives Mfg. Company's history. The names of the entities involved in the tale and their dates of operation are:

- Willis Churchill (1843-ca. 1847)

- J. N. & L. Churchill (ca. 1847-1853)

- The Willis Churchill Manufacturing Company (1853-1857)

- The Hamden Auger Company (1857-1863)

- W. A. Ives & Company (1863-1888)

- The Hamden Manufacturing Company (1888-1905)

- The W. A. Ives Manufacturing Company (1906-ca. 1930)

- The Mephisto Tool Company (ca. 1931-still active)

The William Ives years

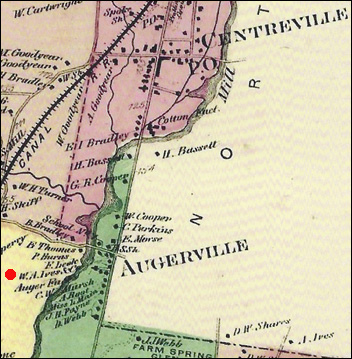

The W. A. Ives Mfg. Company could trace its origins to a factory, dam, and canal built by Willis Churchill in 1843 on the east bank of Connecticut's Mill River, a mile below the village of Centerville. Churchill, a manufacturer of brass surgical instruments, had become interested in the production of auger bits and began manufacturing them at the site. The factory building and homes around it eventually became known as Augerville. The name had staying power; the neighborhood retains the moniker to this day.

Willis Churchill presided over his fledgling enterprise for just a few years. Sometime around 1847, three brothers, J. N. & L. Churchill, formed a company to take over the works and expand the operation. Their relationship to Willis Churchill remains a matter of speculation.(1)

Willis Churchill presided over his fledgling enterprise for just a few years. Sometime around 1847, three brothers, J. N. & L. Churchill, formed a company to take over the works and expand the operation. Their relationship to Willis Churchill remains a matter of speculation.(1)

On March 11, 1853, fire destroyed the Churchill factory. Several of the principals, firm believers in the future of the business, reorganized to form a new entity—the Willis Churchill Manufacturing Company. One of the larger investors, New Haven businessman William A. Ives, became the company's treasurer two years later. The new treasurer was no stranger to the world of finance. He had been an early shareholder of the Pennsylvania Rock Oil Company, the business viewed by many as the prime mover of the Pennsylvania Oil Rush. Unfortunately for his oil-business associates, Ives paid for his shares of the company with securities that proved to be worthless.(2)

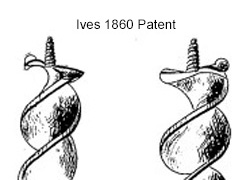

When the Willis Churchill Manufacturing Company reorganized to form the Hamden Auger Company on January 10, 1857, William A. Ives became its president. It took some time for Ives to become interested in product development. During his six years at the helm, he filed for a single patent. The Patent Office awarded him United States Letters Patent No. 29,793 for a double-twist auger bit with a single spur on August 28, 1860. Inspired by the clean holes left by the typical center bit, Ives had come up with an idea that he referred to as a “center auger bit.” His patent application maintained the invention combined the advantages of the lead screw and easy chip passage of an auger bit with the low-friction rotation and smooth cut of a center bit.

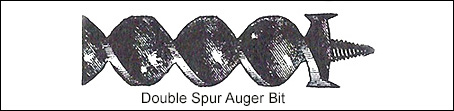

Ives' 1860 auger bit may not have been manufactured. Most surviving Hamden Auger Company bits are of the standard double-spur type. The design features a pair of spurs that extend above and below the floors of a pair of cutting lips. One advantage of the double-spur is the built-in redundancy of its spurs. If either of the downward-facing spurs is broken off, the remaining upward-pointing spur retains its ability to score the edges of the hole.

On March 27, 1863, the Hamden Auger Company reorganized and became W. A. Ives & Company. Ives retained his presidency. Little is known about the first years of the new company's operation, but in the fall of 1868, a now sixty-four-year-old W. A. Ives patented an expansive bit and a hollow auger—the first two in a series of twenty-five patents awarded him while company president. The last of the patents was issued in 1885 when Ives was eighty-one years old. While all of his patents involved boring tools, just four covered auger bit design. The remainder included improvements to bit braces, T-auger handles, hollow augers, a bung borer, and a process for forming lips on auger bits. Ives' most successful inventions proved to be his auger handles and bit braces. Most of them made it to the market in one form or another, and several contributed much to the company's prosperity.

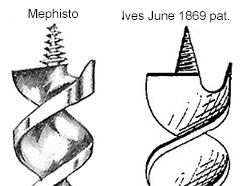

In June 1869, Ives returned to the idea of the center auger bit he'd explored in his 1860 design. The angle of the cutting lip aside, the profile of the 1869 bit's cutting head bears a striking resemblance to that of the Mephisto bit the Ives Company would market forty years later. Though Letters Patent No. 90,755 does not refer to Ives' invention as a "center auger bit", it states that "the labor in its construction is less than either for a centre or auger-bit, and all the advantages of both are combined into one." While the similarity of the bits' profiles is interesting, a direct line of descent between the designs is unlikely. Ives would have been dead for twenty years by the time the W. A. Ives Mfg. Company introduced its flagship Mephisto bit.

In June 1869, Ives returned to the idea of the center auger bit he'd explored in his 1860 design. The angle of the cutting lip aside, the profile of the 1869 bit's cutting head bears a striking resemblance to that of the Mephisto bit the Ives Company would market forty years later. Though Letters Patent No. 90,755 does not refer to Ives' invention as a "center auger bit", it states that "the labor in its construction is less than either for a centre or auger-bit, and all the advantages of both are combined into one." While the similarity of the bits' profiles is interesting, a direct line of descent between the designs is unlikely. Ives would have been dead for twenty years by the time the W. A. Ives Mfg. Company introduced its flagship Mephisto bit.

Though Ives Manufacturing produced bits protected by its president's June 1869 design, not many have survived, a circumstance indicating they did not remain in production for long. On the other hand, the Mephisto bit, developed in 1908, was a success. The Mephisto was not patented, perhaps because there was so little original about it. The company protected its investment with a trademark instead, a protection it soon extended to other tools.

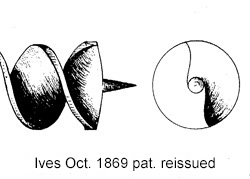

Ives' June 1869 patent appears to have marked the end of his fascination with a "center auger bit." Four and one-half months later, on October 12, 1869, he moved in a new direction with a patent for a double-twist, gouge-lip spurless auger. The cutting head featured lips that sloped away from the lead screw, creating the "gouge shape." The outside ends of the cutting lips terminated in side cutters. The gouge-lip cutter was not original to Ives, and he was aware of it, stating: "I do not wish to be understood as broadly claiming a gouge-lip auger, as such, I am aware, is not new ..."(3)

Ives' June 1869 patent appears to have marked the end of his fascination with a "center auger bit." Four and one-half months later, on October 12, 1869, he moved in a new direction with a patent for a double-twist, gouge-lip spurless auger. The cutting head featured lips that sloped away from the lead screw, creating the "gouge shape." The outside ends of the cutting lips terminated in side cutters. The gouge-lip cutter was not original to Ives, and he was aware of it, stating: "I do not wish to be understood as broadly claiming a gouge-lip auger, as such, I am aware, is not new ..."(3)

Ransom Cook had patented a well-known version of the gouge-lip auger as early as 1851. William A. Ives' contribution lay in his bit's side cutters. Ives' initial patent award displayed only a side view of the bit's cutting head.

He had the document reissued in 1871 with a view of the top of the bit, a move that did much to clarify the design.(4) Though Ives' October 1869 patent was manufactured, it must not have sold well. The author knows of a single example.

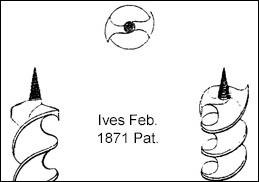

Ives patented his last auger bit in 1871. Though he did not consider Letters Patent No. 111,648 to be a design for a gouge-lip auger, it was. The bit came about as close to Cook's 1851 design as possible while still exhibiting a degree of originality in the angle of its cutting lips.

W. A. Ives' fascination with Ransom Cook's design would eventually get him into trouble for patent infringement, and not for the first time. In 1876 the Millers Falls Company sued the W. A. Ives & Company in the Connecticut District of the Circuit Court of the United States for infringing on its Horton and Amidon chuck patents. At issue were four Ives braces: the "Ives" brace, the "Ives Novelty" brace, the "Centennial" brace, and the "Centennial Novelty." When the case was decided in the courtroom of Judge Nathaniel Shipman in March of the following year, Ives lost and was enjoined from further production of the braces.(5)

A month later, Ives & Company again found themselves on the wrong side of an argument in Judge Shipman's courtroom. The case, Bruff v. Ives, involved the rights to a machine for making gouge-lip augers. The machine had originally been developed by James Swan, the superintendent and general manager of the Douglas Manufacturing Company's plant in Seymour, Connecticut. Swan patented the device in June 1868 and in 1873, assigned the rights to Richard P. Bruff, the business manager of the Russell & Erwin Mfg. Company of New York. The dispute involved United States Letters Patent Reissue No. 5,624. Ives & Company argued that Swan's innovation added nothing but a die to a machine patented by Ransom Cook twenty years earlier. Judge Shipman did not agree and found for Bruff.(6)

In 1880, Ives & Company once again found itself at the center of a patent dispute involving Ransom Cook's bit. The James Swan Company, successor to the Douglas Mfg. Company, took Ives & Company to court to stop their manufacture of the Cook auger. The details of the case, which took place in the Connecticut Court of Common Pleas, are murky. Ives & Company may have been manufacturing a close copy of the bit or perhaps, the bit itself. The court ruled against Ives.(7) Ives & Company either came to an agreement with James Swan or found a way around the ruling. Notice of discounts for the "Ives circular lip" auger appeared in the trade literature from 1880 through at least 1898, often appearing next to listings for "Cook's circular lip" augers made by the New Haven Copper Company and James Swan.(8)

Most of the bits sold by Ives & Company in the latter quarter of the 19th century were standard double-spur bits or knockoffs of the Russell Jennings extension-lip bits. The company stamped the shanks of most of them "W. A. Ives & Co. Extra." The term extra was intended to draw attention to the superior quality of the cast steel used in their manufacture. Price lists appearing in the trade journal Iron Age reveal Ives & Company used the term from as early as 1873 to at least 1898.

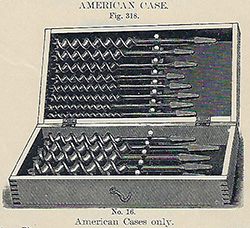

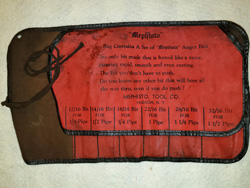

When the market for boxed auger bit sets took off in the early 1890s, the company followed the lead of a number of auger manufacturers in choosing to purchase inexpensive generic boxes rather than design its own. W. H. Bingham, a large Cleveland, Ohio, hardware firm, referred to the design as the "American Case" and sold the boxes with or without bits. The American Case utilized individual spring-type clips wood-screwed to a transverse bar to hold bits in place. It was not patented. Typically lined with red or black paper, versions of varying quality and wood types are seen. A casual survey indicates the Ives Company had a preference for red interiors. The source of the company's American cases is unknown.

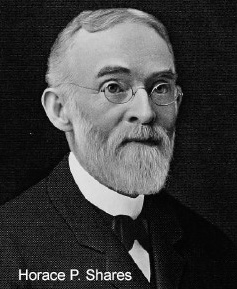

In the mid-to-latter 1880s, William Ives stepped back from the active management of Ives & Company. Board member and local businessman Horace P. Shares succeeded him as president. A pioneer in the development of Quinquennial Valley brick making, Shares opened a previously unknown clay bed in 1863, began burning bricks, taking advantage of every advance in technology, and setting an example for area competitors. Already affluent when he took over for William Ives, Shares turned over the management of his brick-making business to his son in 1887.(9) The decision was likely related to the declining health of W. A. Ives.

William A. Ives died in New Haven on May 24, 1888, at the age of 84. The successful business he built, and the twenty-six patents awarded him, represented an impressive achievement. His questionable business practices aside, Ives appears to have been a creative and well-respected gentleman who enjoyed the pleasures of life in New Haven, his city of residence. He subscribed to a number of charitable causes and was active in his church. His son Brayton went on to serve as president of the New York Stock Exchange, and his son Hubert became a manufacturer in Montreal. His daughters married well. After his death, a group of local businessmen purchased the company he founded and named it the Hamden Manufacturing Company. The enduring strength of the brand Ives built is evident by his successors' 1906 decision to rename the business the W. A. Ives Manufacturing Company—eighteen years after his death.

The Hamden Manufacturing Company

William Ives' son-in-law, New York Publisher Charles Holt, served as executor of his estate and arranged for the sale of the company. He advertised the business in the local New Haven newspaper five months after Ives' passing.(10) The salient points of the notice were:

William Ives' son-in-law, New York Publisher Charles Holt, served as executor of his estate and arranged for the sale of the company. He advertised the business in the local New Haven newspaper five months after Ives' passing.(10) The salient points of the notice were:

The factory is situated four miles from New Haven, Conn., on the road running through Whitneyville, and the drive is exceptionally agreeable. The property includes two factory buildings and machinery, a large tenement and a good cottage, good water-power, and steam engine, good-will, and the stock finished and in the course of manufacture of Augers, Bits, Braces and kindred tools; many of them patented. The works are running full force and time, and are so organized that experience is not essential to the purchaser. Many of the employees own their own dwellings near the factory, and most of them have been connected with it for very many years.

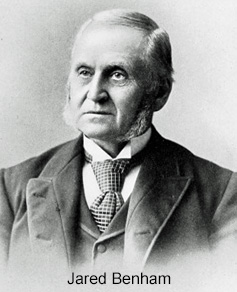

Horace P. Shares, the president of W. A. Ives & Company, stayed on in his position until May 11, 1888, when he and the investors who bought the company organized a new corporation, the Hamden Manufacturing Company (not to be confused with the earlier Hamden Auger Company). They elected Horace Shares as president of the new company. Major investors included the former Ives superintendent Jared Benham, his sons Jared A. and Charles I., and James Surplices, the company's New York sales agent. Jared Benham, the largest shareholder, served as company treasurer and plant superintendent. Charles I. Benham became company secretary and Jared A. Benham joined the business as an employee. The combined shares of the Benhams gave them a controlling interest in the company.

By March of 1893, American augermakers were producing so many standard augers and bits that they had become a commodity. A soft economy only compounded the problem. A group of ten augermakers responded by forming the American Auger and Bit Association, an organization whose primary purpose was to set prices for various categories of augers, a practice sometimes referred to as price fixing. the Hamden Manufacturing Company Mfg. became a charter member. Notable among the non-participants were the Irwin Auger Bit Company whose unique designs were protected by patent, and the Russell Jennings Mfg. Company whose bits commanded a premium. The organization remained active for some dozen years.(11)

Though Hamden Manufacturing continued to market its boring tools under the well-known W. A. Ives name, a scan of the trade literature shows few new products. Horace P. Shares had begun wintering in Florida and soon became the proprietor of a luxury accommodation known as the New Rockledge Hotel. The Florida investment, coupled with a decline in his health, resulted in his spending more and more time away from New Hamden. For all intents and purposes, Shares served as company president in name only.

As Horace Shares faded from the picture, Jared Benham, a man who understood the workings of the Augerville plant better than any other, took on increasing responsibilities. A lifelong resident of Augerville, he had first affiliated with the business as a hand back in the days of Willis Churchill & Co. and worked his way up to the position of plant manager. When William A. Ives reorganized the operation to form his Hamden Auger Bit Company after the disastrous fire of 1853, Benham stayed on as plant superintendent. He continued in the position when Ives reorganized Hamden Auger to form W. A. Ives & Company a decade later and became a shareholder.(12) Benham, his sons, and a grandchild held a controlling interest in the Hamden Mfg. Company.

As Horace Shares faded from the picture, Jared Benham, a man who understood the workings of the Augerville plant better than any other, took on increasing responsibilities. A lifelong resident of Augerville, he had first affiliated with the business as a hand back in the days of Willis Churchill & Co. and worked his way up to the position of plant manager. When William A. Ives reorganized the operation to form his Hamden Auger Bit Company after the disastrous fire of 1853, Benham stayed on as plant superintendent. He continued in the position when Ives reorganized Hamden Auger to form W. A. Ives & Company a decade later and became a shareholder.(12) Benham, his sons, and a grandchild held a controlling interest in the Hamden Mfg. Company.

When Horace P. Shares resigned as company president due to his health, Jared Benham replaced him. His tenure may not have been a long one. Shares passed away in January of 1902 and Benham in May on his 80th birthday. The combination of Benham's age and Shares' lack of involvement in the operation left the business a shell of the dynamic company founded by William A. Ives. Charles J. Benham, Jared Benham's grandson, succeeded him as company president. The younger Benham had been in charge of the company's sales since 1891 and would approach the top job with more energy than his grandfather.

Eleven months after Jared Benham's death, the directors sold the company's Augerville property to the New Haven Water Company which was interested in acquiring the land because of its proximity to the artificial impoundment known as Lake Whitney. Fortunately, Hamden Auger did not have to relocate immediately. In February 1904, Horace Shares' widow Susan tried to force the company into receivership alleging that under the Benhams' mismanagement the value of the company had declined from fifty to twenty thousand dollars.(13)

A request for an injunction to prevent the Benhams from selling their stock accompanied the lawsuit. Susan Shares found an unlikely ally in Jared Adelbert Benham, one of the defendants in the suit, who requested an injunction "to prevent the officers of the company from paying out money to themselves." His action was taken in response to Susan Shares' allegation that "the officers have used up all the income of the company in paying salaries." After months of wrangling, the case was settled that summer when Jared Adelbert Benham withdrew his complaint, and Susan Shares' stock was purchased at assessed value by the Benhams.(14)

In September 1905, the Hamden Mfg. Company moved to an existing factory building on North Cherry Street in Wallingford, eight miles away. The demolition of the Augerville plant by the New Haven Water Company began the same month.

The W. A. Ives Manufacturing Company

The reputation of the tools developed by William A. Ives in the previous century was such that the Hamden Manufacturing Company decided to capitalize on it by reinforcing its connection to the prolific inventor. Since most of the tools sold by the company were already branded with the Ives' name, the idea made sense. The directors adopted the name W. A. Ives Manufacturing Company in 1906 (not to be confused with the earlier W. A. Ives & Company).

Charles J. Benham, the grandson of Jared Benham, became president and injected new life into W. A. Ives Mfg. The sales of the operation's bit braces had always been strong, but sales of its augers had languished. Under his direction, the company developed a new bit, the product that would carry W. A. Ives Manufacturing through the last decades of its existence.

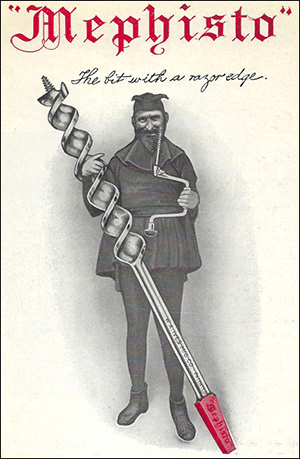

It is not surprising that the success of the Mephisto auger bit had more to do with savvy marketing than a breakthrough in design. Company president C. J. Benham, with his extensive background in sales, was personally involved with its development. Though the quality of what would become the company's flagship bit was first-rate, it was a fairly typical double-twist auger with a single cutter and spur.

The company introduced the bit with much fanfare and hyperbole. A researcher with access to an early catalog reported:

The brand was developed by C. J. Benham. A period catalog tells us that for eight months behind locked doors with an expert tool maker, Mr. Benham struggled with the development of a bit worthy to receive the name "Mephisto". The story is dramatically told how twenty experts from throughout the country were consulted to determine if the bit could be improved. Finally, a bit was produced which, according to the company, was the best in the nation.(15)

For all his marketing expertise, C. J. Benham's first attempt at branding the auger did not go well. He released the bit in the summer of 1908 as the "Red Devil."(16) Though the name was not trademarked for use on tools, the Smith & Hemenway Company had the exclusive use of the term for its razors. At the time, razors were considered part of the hardware trade, and the Ives Company's use of the slogan "the bit with a razor edge" for its auger came perilously close to infringement. Though there is no record of a court case, a "cease-and-desist" letter may have been sent, or perhaps the Ives Company simply wanted to avoid confusion, for the name was soon changed to Mephisto.

The Ives operation's Red Devil bit premiered in New England with demonstrations in hardware store display windows. The company put a small troupe of employees on the road with tools and display kits. One writer described a typical demonstration of the new bit:

These demonstrators are competent not only to show in convincing manner by actual use the salient merits of the tool, but also arrange in connection with the demonstration in each instance attractive window displays. Usually, a young man in the window costumed as a Red Devil captures the crowd's fancy and gives actual demonstrations of the Bit.(17)

The Patent Office records Ives Manufacturing's first use of the Mephisto brand in October 1909.(18) The company re-released the Red Devil bit under the new name and recycled as much of the original promotional material as possible, retaining its original costumed devil images and the "bit with the razor edge" slogan. By 1913, the Smith & Hemenway Company had added miter boxes, pliers, nippers, screwdrivers, and pocket levels to its Red Devil line, and ironically, a product labeled Red Devil auger bits.

When it came to competing for the attention of the buying public, the manufacturers of the Red Devil bit were late to the table. The scale of Charles J. Benham's marketing campaign dwarfed his earlier effort. Sales representatives dressed in full Mephisto costume conducted demonstrations in the hardware stores of major U. S. cities from coast to coast. Benham's Faustian Mephistos bored holes in hardwood with bits that had just cut through bricks and bored through pieces of twenty-gauge steel sandwiched between oak planks.(19) Gimmicks aside, the steel in the bits was first-rate. The Mephisto bit cut clean, and it cut fast. It was a tool for getting the job done.

W. A. Ives Mfg. was a small company, employing something on the order of eighty employees. The development of its Mephisto line represented a major effort. In addition to its standard bit, the company's preliminary ten-page catalog featured screwdrivers, electricians' bits with fast lead screws, car bits with a longer twist, and an expansive bit.(20) The Mephisto auger, with its distinctive, red-painted tang, proved a howling success—so much so that the operation soon found the need to refocus its energies. In 1911, the company decided to outsource the manufacture of bit braces and sold the machinery for producing them to the Southington Mfg. Company, a Connecticut-based business located in the borough of Southington, some twenty-five miles away.(21)

In 1914, Ives Manufacturing added chisels and a bit brace to its Mephisto lineup. The chisels, with a one-piece blade, shank, and head were virtually identical to the Everlasting brand sold by the Stanley Rule & Level Company. The George E. Wood Tool Company, located in Southington, was a subsidiary of Stanley Rule, and the Mephisto chisels were almost certainly produced there. The manufacturer of the Mephisto brace was most likely Southington Mfg., the company that purchased Ives Mfg.'s brace-making setup. An examination of a 1915 Ives catalog reveals that the company had added sap-tapping, plumbers', and sill-boring bits to its Mephisto offerings and sold a smaller, second-quality line of braces, screwdrivers, and augers under the Ives name. Sets of Mephisto auger bits were available in either canvas rolls or Bartlett boxes.(22)

The W. A. Ives Mfg. Company became a top-to-bottom union shop in 1915. As a result, the Metal Trades Department of the American Federation of Labor

authorized it to stamp its tools with a union shield bearing the inscription "UNION LABEL" followed by the initialism " M. T. A. F. OF L." The union affiliation came with its plus and minuses. Ives Mfg. was the only unionized auger bit manufacturer in the country. Its costs went up and several of the large hardware jobbers canceled their orders. On the flip side, the company could use the American Federation of Labor seal to promote its products to workmen sympathetic to union causes. W. A. Ives Mfg. missed few opportunities to do so.(23)

The W. A. Ives Mfg. Company became a top-to-bottom union shop in 1915. As a result, the Metal Trades Department of the American Federation of Labor

authorized it to stamp its tools with a union shield bearing the inscription "UNION LABEL" followed by the initialism " M. T. A. F. OF L." The union affiliation came with its plus and minuses. Ives Mfg. was the only unionized auger bit manufacturer in the country. Its costs went up and several of the large hardware jobbers canceled their orders. On the flip side, the company could use the American Federation of Labor seal to promote its products to workmen sympathetic to union causes. W. A. Ives Mfg. missed few opportunities to do so.(23)

The company's ability to sell its popular tools eventually exceeded its ability to manufacture them. The situation came to a head in September 1923 when C. J Benham and the company attorney arranged for a $300,000 bond issue to fund an expansion of the plant. The announcement of the bond sale took place at a time when the firm lacked the capital for the raw material needed to fill several massive orders from the railroad industry. Three months later, a several major stockholders revolted, accused the firm of mismanagement, petitioned for a court-appointed receiver, and asked that the company be dissolved.(24)

The plot thickened when the Chairman of the Board and another director joined the group, alleging that the Board had not authorized the bond issue and was being denied access to the books. Though Benham and his allies responded by buying out the shares of the stockholders, the receivership was granted.(25)

Things went from bad to worse the following year. On April 20, 1926, a fire laid waste to the two-story wooden factory housing the Ives Mfg. Company's operation. The blaze was so intense it destroyed a nearby house, jumped a neighboring street, burned a section of the local freight depot's platform, and set the roofs of seven additional houses ablaze. Manufacturing ceased and plans for rebuilding were put on hold pending the settlement of insurance claims. In October the company announced it would remain in Wallingford and begin construction of a new brick plant on the old site.(26)

The construction of the new plant never happened. In late 1926, the W. A. Ives Mfg. Company took up temporary quarters in the former Millers Brothers Cutlery factory in nearby Meriden and never moved out. A catalog issued in early 1929 indicates the company no longer sold the Mephisto version of the Everlasting chisel, but includes auger bits, all-steel wood chisels, cold chisels, star drills, hammers, and hacksaw frames.(27) With the onset of the Great Depression, the company struggled financially, and debts mounted. Ives Mfg. may have already been moribund in March 1931, when the local newspaper reported that the owner of a die-sinking business had injured himself in the unlit factory while looking for the yard superintendent.(28)

The Mephisto Tool Co. of Hudson New York

The demise of the W. A. Ives Mfg. Company did not mean the end of the Mephisto bit. Manufacture of the augers moved to the Mephisto Tool Company of Hudson, New York. The Hudson firm acquired the Mephisto trademark and the Ives product line. It continued to use such Ives promotional slogans as the "The bit you don't have to push." Most of the Mephisto Tool Company's early single-lip augers bear a striking resemblance to those manufactured by Ives Manufacturing, so it would not be unreasonable to assume that at least some of the Ives Company's equipment and an employee or two made the eighty-six-mile journey to Hudson plant. The direct descendant of the early Mephisto Tool Company operates under the same name in Hudson today. As of this writing, its primary products are caulking irons and cold chisels.

Illustration credits

- Map of Hamden: Beers. F. W. et AL. The Atlas of New Haven County, Connecticut: from Actual Surveys. New York : F. W. Beers, 1868.

- Ives 1860 bit: United States Letters Patent No. 29,793

- Double-spur auger: Woodworkers' Tools, Supplies, Machinery, and Similar Goods ... Detroit, Michigan : Charles A. Strelinger & Co., 1897.

- Ives 1869 and Mephisto bits compared: United States Letters Patent No. 95,803 and Catalogue No. 1: The W. A. Ives Mfg. Co. Wallingford, Connecticut : W. A. Ives Mfg. Co., ca. 1915.

- Images of Ives Jennings bits in American cases: authors photos.

- H. P. Shares portrait: Commemorative Biographical Record of New Haven County, Connecticut: Containing Biographical Sketches of Prominent and Representative Citizens ... Chicago: J. H. Beers & Company, 1902.

- Jared Benham portrait: Commemorative Biographical Record of New Haven County, Connecticut: Containing Biographical Sketches of Prominent and Representative Citizens ... Chicago: J. H. Beers & Company, 1902.

- Mephisto Devil with auger bit: Mephisto: Catalogue No. 19. Wallingford, Connecticut : W. A. Ives Mfg. Co., [not dated but 1915.]

- Plumber's bit: Mephisto: Catalogue No. 19.

- Auger bit rolls & Mephisto bits in Bartlett's box: author's photos.

- Mephisto Tool Company devil: "Mephisto" Tools Price List: November 1, 1937. Hudson, New York : Mephisto Tool Company, 1937.

- Plumbers' bits and roll: author's photos.

References

- The early years of the company are not well documented and at times, the sources give conflicting information: Rockey, J. L., ed. History of New Haven County Connecticut, vol. 1. New York : W. W. Preston, 1892. p. 307; Hill, Everett G. A Modern History of New Haven and Eastern New Haven County, vol. 1. New York : S. J. Clarke. 1918. P. 346; Blake, William P. ed. History of the Town of Hamden, Connecticut, with an Account of the Centennial Celebration, June 15, 1886. New Haven : Price Lee and Co., 1888. p. 144.

- Henry, J. T. The Early and Later History of Petroleum With Authentic Facts in Regard to its Development in Western Pennsylvania … Philadelphia : Jase. B. Rogers Company, 1873. p. 80.

- United States Letters Patent No. 95,803.

- United States Letters Patent Reissue No. 4,156.

- Catchword, Samuel. Reports of Cases Argued and Determined in the Circuit Court of the United States for the Second Circuit: Vol. XIV. New York : Baker, Voorhis & Co., 1879. p. 198-204.

- Banning, Hubert A. and Henry Arden. Reports of Patent Cases Decided in the Circuit Courts of the United States since January 1, 1874: Vol. II. New York : L. K. Strouse, 1882. p. 595-600.

- "Court of Common Pleas—Judge Harrison." New Haven Morning Journal and Courier (New Haven, Conn.), Dec. 17, 1880. p. 4.

- Too many occurrences to cite individually, but found in such trade periodicals as The Iron Age, Hardware: devoted to the American Hardware Trade, and The Age of Steel.

- Commemorative Biographical Record of New Haven County, Connecticut: Containing Biographical Sketches of Prominent and Representative Citizens ... Chicago: J. H. Beers & Company, 1902. p. 85.

- "For Sale! the Business of W. A. Ives & Co." The Morning Journal-Courier (New Haven, Conn.), Oct. 3, 1888. p. 3.

- "Augers and Bits." The Iron Age. (March 16, 1893). p. 635.

- Commemorative Biographical Record of New Haven County, Connecticut: Containing Biographical Sketches of Prominent and Representative Citizens ... Chicago: J. H. Beers & Company, 1902. p. 389.

- "Wants Receivers Appointed." New Haven Morning Journal and Courier (New Haven, Conn.), Feb. 17, 1904. p. 2.

- New Haven Morning Journal and Courier (New Haven, Conn.), June 18, 1904. p. 9; July 1, 1904. p. 6; Aug 12, 1904. p. 8.

- Price, James E. A Sourcebook of United States Patents for Bitstock Tools and the Machines That Made Them. 1st Approximation. Naylor, Missouri : James E. Price, 1992. p. 34.

- "Window Display Showing the Process of Making Auger Bits." Hardware: a Review of the American Hardware Market. vol. 37, no. 8 (July 25, 1908). p.28. (Periodical also has alternative subtitle: Devoted to the American Hardware Trade)

- "Red Devil Auger Bit Demonstrations." The Iron Age. August 27, 1908. p. 601.

- W.A. Ives Manufacturing Company. Augers, Auger Bits, Machine Bits. US 71040156, United States Patent and Trademark Office, June 1, 1909.

- "The Auger Bit Industry." Record-Journal (Meriden, Connecticut), May 8, 1922, p. 8.

- Mephisto: Preliminary Catalogue. Wallingford, Connecticut : W. A. Ives Mfg. Co., ca. 1910.

- Untitled. The Iron Age. May 4, 1911. p. 1027.

- Mephisto: Catalogue No. 19. Wallingford, Connecticut : W. A. Ives Mfg. Co., [not dated, but 1915.]

- Proceedings of the Ninth Annual Convention of the Union Label Trades Department, American Federation of Labor Held at San Francisco, Cal. Nov. 23-27, 1915. Washington, D. C. : A. F. of L., 1916. p.84.

- "Ives Co. Expansion Now Being Planned." The Journal (Meriden, Connecticut). Sept. 22, 1923, p. 4; "W. A. Ives Co. Stockholders Petition for Receivership." Record-Journal (Meriden, Connecticut). Jan 7, 1924, p. 8.

- "Ives Co. Directors Ask for Receiver in Wallingford." The Journal (Meriden, Connecticut). 15 May 15, 1924, p. 1; "Stockholders Prohibit Load for W. A. Ives Company Officials." Record-Journal (Meriden, Connecticut)) June 23, 1925, p. 8.

- "$300,000 Morning Fire at Wallingford Destroys W. A. Ives Manufacturing Plant." The Journal (Meriden, Connecticut), April 20, 1926, p. 15; "Ives Company to Build Here with Plant on Old Site." The Journal (Meriden, Connecticut), Oct. 5, 1926. p. 24.

- List Prices.: "Mephisto" Tools. Meriden, Connecticut : W. A. Ives Mfg. Co., Feb. 1, 1929.

- "W. A. Ives Mfg. Co. in Financial Difficulty." Record-Journal (Meriden, Connecticut), Oct. 5, 1930, p. 5; "M. T. Marchand Injured in Fall." Record-Journal (Meriden, Connecticut), Mar. 16, 1931. p. 2.