Featured Hand Drills

Henry L. Pratt's chuck

On August, 14, 1877, Henry L. Pratt of Brooklyn, New York, received United States patent no. 194,109 for his 'improvement in drill-chucks.' Pratt, the president of the Millers Falls Company, was issued the patent for a springless, two-jaw chuck, a device designed to accept diamond-shaped drill points with a maximum diameter of 1/8 inch. The chuck, used on most of the company's drills until 1896, is seen here mounted on an example of Model No. 1, one of the first hand drills to be offered by the Millers Falls Company. Appearing in the company's catalogs as early as 1878, early variations on the basic drill were available in both long and short spindle versions. The short spindle models were equipped with a single pinion. The long spindle versions featured a second pinion gear.

On August, 14, 1877, Henry L. Pratt of Brooklyn, New York, received United States patent no. 194,109 for his 'improvement in drill-chucks.' Pratt, the president of the Millers Falls Company, was issued the patent for a springless, two-jaw chuck, a device designed to accept diamond-shaped drill points with a maximum diameter of 1/8 inch. The chuck, used on most of the company's drills until 1896, is seen here mounted on an example of Model No. 1, one of the first hand drills to be offered by the Millers Falls Company. Appearing in the company's catalogs as early as 1878, early variations on the basic drill were available in both long and short spindle versions. The short spindle models were equipped with a single pinion. The long spindle versions featured a second pinion gear.

The firm's original vision for its eggbeater hand drills was one of smaller tools designed for light work. As time passed, however, improvements in bit holding technology and a growing understanding of the utility of the eggbeater drill resulted in the company marketing larger-sized hand drills capable of holding bits of greater diameter. Originally 10 1/2 inches in length, by 1909 the re-designed No. 1 had grown to 12 1/2 inches and was equipped with a three-jaw, spring-type chuck, a detachable side handle, and a ball thrust bearing.

McCoy's three-jaw chuck

Pratt's chuck was supplanted by the three-jaw chuck patented by William H. McCoy on September 29, 1896. McCoy, a company employee, had been issued a patent for a rotating brace handle in 1871 and a patent for adding a pair of spring-type jaws to Barber's improved chuck in 1890. The jaws in McCoy's hand drill chuck are held in place by pins which move back in forth within recesses cut into the chuck's socket, remaining in easy alignment as they are tightened on the shank of a drill. Relatively inexpensive to manufacture and highly reliable, McCoy's chuck is among the finest springless, three-jaw chucks to have been developed for the hand drill. In total, McCoy registered seven patents while employed by the Millers Falls Company; at least five were put into production.

Pratt's chuck was supplanted by the three-jaw chuck patented by William H. McCoy on September 29, 1896. McCoy, a company employee, had been issued a patent for a rotating brace handle in 1871 and a patent for adding a pair of spring-type jaws to Barber's improved chuck in 1890. The jaws in McCoy's hand drill chuck are held in place by pins which move back in forth within recesses cut into the chuck's socket, remaining in easy alignment as they are tightened on the shank of a drill. Relatively inexpensive to manufacture and highly reliable, McCoy's chuck is among the finest springless, three-jaw chucks to have been developed for the hand drill. In total, McCoy registered seven patents while employed by the Millers Falls Company; at least five were put into production.

The No. 7 drill seen here was manufactured about 1909 and is equipped with McCoy's chuck. Its drive gear is four inches in diameter—somewhat larger than typical for a drill of this length. The slightly oversize gear in combination with a long, narrow crank handle results in an exceptionally well-proportioned tool. The No. 7 was created as a mid-priced model, and early models were unplated and domestic hardwood used in production at a time when tropical woods were the norm. The drill is steel bodied, rather than of malleable iron, and the variation pictured features an adjustable take up that was used on no other drill. The adjustment allows the owner to compensate for inevitable wear that results in a wobbly main gear on a heavily used drill.

A bit storage solution

A popular feature found on many hand drills is a hollow head that provides a cavity for the storage of small sized bits. Access to the hollow is typically provided via a screw off cap at the top end of the handle. The screw off cap design is plagued by one major problem. The end cap is prone to loosening during the drilling operation. Over tightening the cap is a poor solution to the problem as the wooden threads are easily damaged. Pictured here is the No. 3 hand drill from, perhaps, 1910. This small, single speed tool is equipped with a rotating barrel-type lock that allows access to the storage area in the tool's elongated hollow head. The design avoids some the problems associated with screw

off end caps, but has a weakness of its own. The design was unfamiliar enough that some users did not realize that the ring below the sheet metal barrel needed to be loosened before the locking tab could be maneuvered free of its retraining boss. Trying to muscle one's way into the storage hollow inevitably leads to a damaged lock. The drill's elongated head was designed to provide additional storage space for twist type bits, which are longer than traditional drill points.

A popular feature found on many hand drills is a hollow head that provides a cavity for the storage of small sized bits. Access to the hollow is typically provided via a screw off cap at the top end of the handle. The screw off cap design is plagued by one major problem. The end cap is prone to loosening during the drilling operation. Over tightening the cap is a poor solution to the problem as the wooden threads are easily damaged. Pictured here is the No. 3 hand drill from, perhaps, 1910. This small, single speed tool is equipped with a rotating barrel-type lock that allows access to the storage area in the tool's elongated hollow head. The design avoids some the problems associated with screw

off end caps, but has a weakness of its own. The design was unfamiliar enough that some users did not realize that the ring below the sheet metal barrel needed to be loosened before the locking tab could be maneuvered free of its retraining boss. Trying to muscle one's way into the storage hollow inevitably leads to a damaged lock. The drill's elongated head was designed to provide additional storage space for twist type bits, which are longer than traditional drill points.

The drill depicted here has little in common with an earlier drill designated No. 3 and marketed in the 1880s. The earlier version featured a malleable iron, rather than steel, frame and was equipped with an elongated hollow head for twist drills with access to the storage area was via a traditional screw-off end cap. The the three-jaw chuck and detachable side handle which characterize the later version are not seen on the early drill. The No. 3 seen here predates the incremental design changes that began about 1912 when the company started to paint hand drill gears red and mushroom-shaped side knobs began to appear on drills where tear drop knobs had been the norm.

The Millers Falls box design was replaced with the familiar crimson color about 1915. The lid of the box shown here has faded because of exposure to light. The green seen on the bottom of the box (right side of illustration) is the original color.

The diminutive no. 4

Pictured at right is the smallest crank-type drill that the company offered, the No. 4, a cast iron tool just eight inches long. Although it is often referred to as a jeweler's drill, the primary audience for the tool was that of amateur woodworkers and hobbyists. The tiny drills were especially popular with children and scroll sawyers—groups far larger in number than that of working jewelers. The No. 4 pictured here sports the tiny chuck that was offered at the time the drill was introduced and that remained an option throughout a production history of nearly sixty years. At least four variations of the basic drill were offered by the company. One of them, the No. 4D, was fitted with Pratt's chuck and touted as an excellent choice for use in public schools—a not surprising claim since it was ideally suited to the small hands of younger students. (Shop projects were common at the elementary level in the early 20th century.)

Pictured at right is the smallest crank-type drill that the company offered, the No. 4, a cast iron tool just eight inches long. Although it is often referred to as a jeweler's drill, the primary audience for the tool was that of amateur woodworkers and hobbyists. The tiny drills were especially popular with children and scroll sawyers—groups far larger in number than that of working jewelers. The No. 4 pictured here sports the tiny chuck that was offered at the time the drill was introduced and that remained an option throughout a production history of nearly sixty years. At least four variations of the basic drill were offered by the company. One of them, the No. 4D, was fitted with Pratt's chuck and touted as an excellent choice for use in public schools—a not surprising claim since it was ideally suited to the small hands of younger students. (Shop projects were common at the elementary level in the early 20th century.)

The No. 4 seen here was manufactured during the period when rosewood was used for a crank handle that was fitted directly to the rim of the main gear. The later versions of the drill featured a drive gear cast with a projecting stub to which a crank handle, typically made of domestic hardwood, was attached. The No. 4 hand drill was out of production by 1935.

Two-speed hand drills

Millers Falls introduced its first two-speed hand drills in 1913. The initial offering consisted of three models—Nos. 98, 980 and 981. The drills

differed from one another only in the shape of their hollow heads. The following year, the company added a ratchet option to each of the three models, creating Models 198, 1980 and 1981. A knurled ring shifter allowed the user of the user of the drill to change speeds without removing the bit from the work.

Millers Falls introduced its first two-speed hand drills in 1913. The initial offering consisted of three models—Nos. 98, 980 and 981. The drills

differed from one another only in the shape of their hollow heads. The following year, the company added a ratchet option to each of the three models, creating Models 198, 1980 and 1981. A knurled ring shifter allowed the user of the user of the drill to change speeds without removing the bit from the work.

In size, the two-speed drills occupy a place somewhere in between that of a typical hand drill and that of a breast drill. Drills of this size are unsuited for delicate work because their extra mass imposes a danger of breakage to small, fragile bits. The flexibility of the two-speed models, however, is a boon for the general handyman. The slower speed, with its extra torque, is well suited to powering larger-sized twist drills though softwoods. The higher speed works well with midsize bits and for drilling metals—situations where more revolutions per minute are a plus.

Despite their advantages, the extra cost limited the appeal of the company's two-speed hand drills. Nos. 981 and 1981, drills that featured a detachable breast plate similar to that found on breast drills, had a production of life only three years. Nos. 98 and 198, which featured a flat-topped head similar to the popular No. 2 hand drill, were eliminated by 1922. In an effort to reduce costs, the surviving two-speed models were fitted with cheaper, screw-top heads at about the same time. In 1925, the firm eliminated bit storage from the heads of its two-speed drills altogether. (The drill seen here is from this period.) The Millers Falls Company's two-speed hand drills were out of production by the late 1940s.

The 'Buck Rogers' drills

The nos. 104 and 308 hand drills were introduced in the late 1940s along with a number of other innovatively designed models that have become known as the Buck Rogers tools. The new drills were single speed boring tools offered in direct competition with the company's traditional eggbeater drills. The No. 104 is the smaller of the two drills and has a maximum jaw size of 1/4 inch while that of the No. 308 is 3/8. At the time of their introduction, the two models were the only drills in the catalog to feature an enclosed main gear. The concept was not new to the Millers Falls Company, however. It had featured an enclosed-gear breast drill in its 1938 catalog. While an enclosed gear has the advantage of protecting the mechanism from dirt, it also serves, happily, to keep fingers from getting pinched.

The nos. 104 and 308 hand drills were introduced in the late 1940s along with a number of other innovatively designed models that have become known as the Buck Rogers tools. The new drills were single speed boring tools offered in direct competition with the company's traditional eggbeater drills. The No. 104 is the smaller of the two drills and has a maximum jaw size of 1/4 inch while that of the No. 308 is 3/8. At the time of their introduction, the two models were the only drills in the catalog to feature an enclosed main gear. The concept was not new to the Millers Falls Company, however. It had featured an enclosed-gear breast drill in its 1938 catalog. While an enclosed gear has the advantage of protecting the mechanism from dirt, it also serves, happily, to keep fingers from getting pinched.

Although the price of the Nos. 104 and 308 was comparable to their traditionally designed single speed counterparts, it can be argued that the drills did have an edge in quality. In addition to the main gear being enclosed, it runs on an oilite bushing. The frames of the drills are cast aluminum with a baked enamel finish, the handles an opaque red plastic. Even though the No. 104 pictured here was shipped with drill points, both it and the No. 308 were designed with handles long enough to accommodate twist drills. Both drills were out of production by 1960.

Two best-selling drills

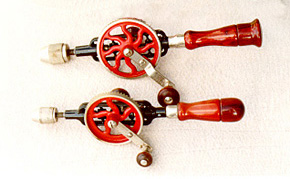

The two eggbeater drills pictured here were manufactured during the period when the company was using an orange varnish stain on the wooden components of its tools. The top drill is the No. 2, the bottom drill, the No. 5. The two models anchored the Millers Falls line of single speed drills for decades and not only survived the introduction of the Buck Rogers drills but continued to be produced long after their more radically designed cousins were cut from the firm's product offerings. The No. 2, renumbered as the 2-01, was still being offered as late as 1984—over 100 years after its introduction.

The two eggbeater drills pictured here were manufactured during the period when the company was using an orange varnish stain on the wooden components of its tools. The top drill is the No. 2, the bottom drill, the No. 5. The two models anchored the Millers Falls line of single speed drills for decades and not only survived the introduction of the Buck Rogers drills but continued to be produced long after their more radically designed cousins were cut from the firm's product offerings. The No. 2, renumbered as the 2-01, was still being offered as late as 1984—over 100 years after its introduction.

In February 1956, Joe Guilbault, a veteran of fifty years in the Millers Falls hand drill department, was interviewed for the firm's employee magazine, Dyno-mite. During his long tenure, Guilbault worked on sixty-one different hand drill models, fitting the gears on more drills than perhaps anyone in the history of the company. Asked if he has a favorite among all the models, Guilbault replied, "The number two, that is it. The best hand drill in all the world. The number five, too. I like two and five best."