Millers Falls Hand Drills

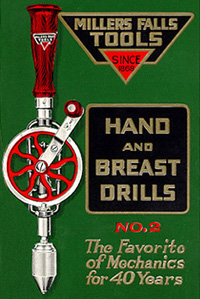

The illustration at right appeared in the company's Catalog No. 40 published in January, 1929. It promotes one of the Millers Falls Company's most popular eggbeater drills, the No. 2. Although the text at the bottom of the illustration would seem to indicate that the No. 2 was introduced in 1889, the company was offering the drill as early as 1878. Having undergone several minor changes in numbering and still part of the line as late as 1981, the century-long production history of the No. 2 easily rates it as one of the best-selling hand drills of all time. The popularity of the Millers Falls Company's drills and bit braces was, perhaps, the single greatest reason for the firm's success until the 1920's, when profits from the sale of power tools and hand planes provided a much-expanded base of financial support.

The illustration at right appeared in the company's Catalog No. 40 published in January, 1929. It promotes one of the Millers Falls Company's most popular eggbeater drills, the No. 2. Although the text at the bottom of the illustration would seem to indicate that the No. 2 was introduced in 1889, the company was offering the drill as early as 1878. Having undergone several minor changes in numbering and still part of the line as late as 1981, the century-long production history of the No. 2 easily rates it as one of the best-selling hand drills of all time. The popularity of the Millers Falls Company's drills and bit braces was, perhaps, the single greatest reason for the firm's success until the 1920's, when profits from the sale of power tools and hand planes provided a much-expanded base of financial support.

The Millers Falls Company was a leader in introducing hand and breast drills to the market place. Its contributions, however, were not quite the earth shaking events that the company's front office liked to make them out to be. In an article in the January, 1915, issue of Hardware Dealers Magazine, a 'special correspondent' (i.e., a company representative) credited the Millers Falls Company with the invention of the hand drill and the idea of adding a chuck to a breast drill. Neither idea originated with the company or its personnel. The firm's contribution lay in the development of commercially successful, mass market versions of these products—a process simplified by an intimate understanding of chucks and bit holding devices.

Hand drills are generally fifteen inches or less in length, are best suited for drilling holes in wood and light metals, and are most effective when used by a worker whose body is positioned above a work piece. They work best when operated at high speed and are especially useful for accurately drilling small-sized holes without damaging delicate drill points. Hand drills are not to be confused with breast drills. Breast drills typically exceed fifteen inches and are topped by a concave plate that provides a surface which the user can lean against when boring a hole. Sometimes referred to as "chest drills," "belly drills" or "knee drills," these tools were indispensable in the construction industry, in blacksmith shops, in factories and in shops where rail cars were fabricated. Ruggedly built, the drills are useful for boring holes in iron, steel and extremely tough wood. Designed with the expectation that a worker would be putting a fair amount of body weight into a task, the breast drills are especially effective when used in a standing position, alongside the work piece.

The distinctions between the two types are not hard and fast, however, and the Millers Falls Company manufactured a handful of tools that did not quite fit into either category. Several of its large hand drills exceeded fifteen inches. (One was even fitted with a breast plate.) Some of the company's breast drills came equipped with a D-type handle, rather than the traditional breast plate. (D-type handles convert breast drills into tools especially useful for workers positioned above or below a work piece. The tools discussed in this part of the web site are those which the company chose to call hand drills; those which the company labeled as breast drills are treated in the breast drill pages.