Charles H. Amidon - Later Bit Braces

The braces pictured here were patented by Charles H. Amidon after he left the Millers Falls Mfg. Company. None of his post-Millers Falls braces are easy to find.

Amidon's 1873 patent

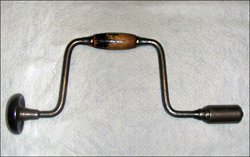

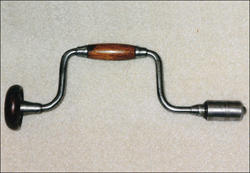

On July 1st, 1873, Amidon was issued United States Letters Patent No. 140,451 for a combination brace and bitstock. While no examples of the device depicted in the patent drawings have been observed, the brace itself was produced in the village of Millers Falls by the Amidon Manufacturing Company. The brace's hinged jaws are made self-opening by the use of a transverse coil spring, and the chuck shell is threaded onto a retractable sleeve. Although it is not evident in the photos, a slot has been cut into the retracting sleeve for its full length—allowing it to fit over a fixed key and facilitating the loosening of the chuck shell. Amidon's post-Millers Falls braces feature swaged retaining rings for holding the sweep handle in place.

Buffalo variant of Amidon's 1873 patent

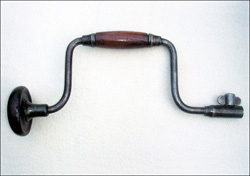

In August 2004, Charles R. Wright of Colorado Springs sent these photographs of a variant of Amidon's 1873 patent. He reported that the markings on the chuck shell were badly worn, but that he could make out the "don" letters of what appeared to be a name and the abbreviation "N. Y." The overall look of the brace indicates manufacture during Amidon's early years in Buffalo—most likely during the partnership of Saxton & Amidon. The photographs document a major change in design—leaf springs have replaced the fragile coil spring that held the hinged jaws in position. Mr. Wright suspected that his brace was an Amidon, but sadly, he passed away before I had learned enough about the 1873 patent to recognize it as a variant.

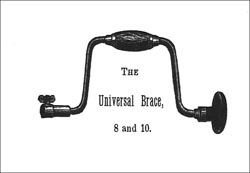

Amidon's Universal Brace (1878)

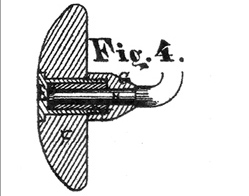

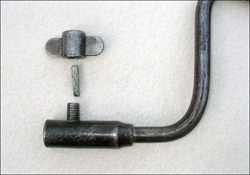

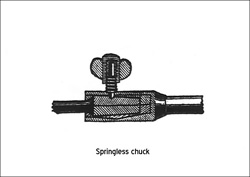

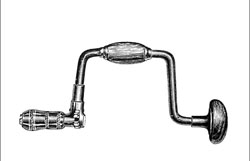

United States Letters Patent No. 201,379, dated March 19, 1878, describes Amidon's design for an inexpensive chuck that uses a hollow wing nut to push a chisel-shaped plunger against the tang of a bit. In theory, the device can be used to hold either round or square-tanged bits. When using a round bit, the worker is expected to turn the plunger so that its edge is parallel to the side of the bit, providing resistance over the entire length of its face. The plunger is rotated 90 degrees to the shaft when using a square-shanked bit. Better in the abstract than in the execution, the chuck is moderately successful in securing square-tanged bits of average size. Average-sized round shank bits, however, are another story. Pushed to the side as the thumbscrew is tightened, the off-center bit creates an eccentric rotation of the brace—resulting in an odd, not entirely pleasant, experience for a woodworker.

Marketed as the Universal Brace, the tool was, perhaps, the least of Amidon's brace designs. The example seen below is unmarked, but the details of its chuck, the shape of its head, and the small diameter of its wrist handle indicate manufacture during the inventor's years with Saxton & Amidon (1877-1883). The drawing of the early, springless version of the chuck is courtesy page 212 of the Buffalo City Directory for the Year 1879, published in Buffalo that year by the Courier Company. That illustration of the later, spring-loaded chuck, with its stepped shell, comes from an Amidon & White advertisement on page 210 of the Buffalo City Directory for the Year 1884, also published in Buffalo by the Courier Company.

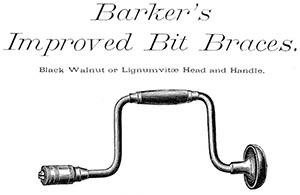

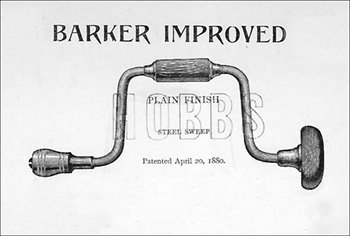

Barker Improved Brace (1878)

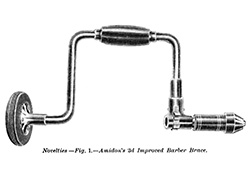

The earliest evidence for the existence of the Barker Improved Brace can be found in an advertisement for the Saxton & Amidon partnership in the Buffalo City Directory for the Year 1878 published in Buffalo by the Courier Company. The earliest illustration of the brace to surface is courtesy of a detached page from an 1885 Hibbard, Spencer & Bartlett Company catalog. The illustration depicts a tool with a classic Saxton & Amidon head, wrist handle, and cylindrical chuck shell. The ca. 1886 illustration below shows the short-chuck version of Amidon's 1880 Patent. It appeared on a page removed from a ca. 1886 catalog for the Hobbs Hardware Company of London, Ontario. By this time, Amidon was in a partnership with former banker Ansley D. White.

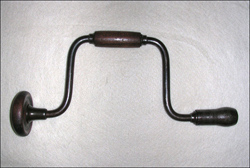

Amidon's 1880 chuck

Charles Amidon's 1880 patent (No. 226,646) was issued while he was a partner in the firm of Saxton & Amidon (1878-1883). It is apparent that he retained the rights to his chuck after he left the firm as examples marked Amidon & White (1883-1887), Amidon and Bastedo (1887-1890) and Amidon Tool Corporation (1894-1898) have been observed. The springless 1880 chuck was well-designed in that it provided a sure grip, was inexpensive to manufacture, and durable. The beauty of the design is often overlooked due to its use on the moderately priced braces manufactured by the Buffalo firms that Amidon became involved with.

Braces equipped with the 1880 patent can be found with a variety of markings and configurations. The Saxton & Amidon brace seen here features a long chuck shell and socket and is fitted with a nicely sculpted head. The shell is stamped "Amidon's Patent July 20, '80. Manf'd by Saxton & Amidon Buffalo, N. Y." The patent was actually issued on April 20th. The short-chuck brace is equipped with a short socket, a short shell, and an unusual economy-grade head with a wooden quill. Unfortunately, the manufacturer's mark on this 'short-chuck' brace is nearly obliterated. Only "Amidon's Pat. July 20" and the 'Buf' in Buffalo remain visible. The Amidon & Bastedo brace shown here features a short socket and a medium-length shell. It is stamped "Manuf'd by Amidon & Bastedo Buffalo, N. Y. Pat Apr. 20 '80."

Amidon's Improved Ratchet Brace (1883)

On August 28, 1883, Charles H. Amidon was awarded United States Letters Patent No. 283,844 for a ratcheting bit stock with a disk-shaped pawl. Although the use of a beveled edge, disk-type pawl was not new to Amidon's design, his idea was considered novel in that the disk pivots on a center pin held captive by a clevis that slides back and forth within a slot. As the spring-loaded disk is rotated, the angles of its beveled edges control the direction in which the brace's ratchet wheel is allowed to revolve. The similarity of Amidon's idea to an earlier design (Pflegar, 1876) may explain the two and one-half year wait between his application and the award of the patent. It could be the inventor needed a fair amount of time to convince the Patent Office of the originality of his creation.

The braces pictured here were fabricated at the time of Amidon's partnership with Ansley White (1883-1887) and are stamped "Amidon's Pat. July 20, 1880. Manufactured by Amidon & White, 135 Main St. Buffalo, N. Y." The patent date references the chuck rather than the ratchet design. The handy knob for rotating the pawl does not appear in the patent drawings. The Amidon & Bastedo partnership (1887-1890) produced braces featuring the 1883 ratchet as well.

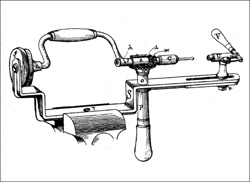

Amidon's Corner Brace (1884)

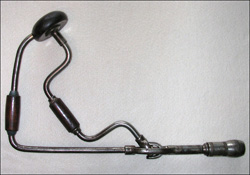

Charles Amidon patented a corner brace while in partnership with Ansley White. The chuck on the example seen below is marked "Amidon's Pat. May 13, 1884. Manufactured by Amidon & White, 135 & 137 Main St. Buffalo, N. Y." The basic design of the tool—an L-shaped frame with an angled crank resembling a standard bit brace—became the predominant pattern for most of the corner braces manufactured in the twentieth century. Amidon's patent (No. 298,542) made allowances for both universal joint and geared linkages. The brace seen here features a universal joint.

Amidon's Globe Jaw Chuck (1884)

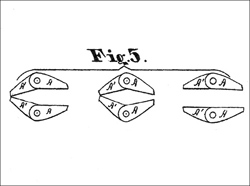

Certainly the most unusual of Amidon's brace patents was that for the chuck he patented on September 16, 1884 (No. 305,263). The chuck features two massively oversized, pivoting jaws that are adjusted by a tapered wing nut. As the tapered nut is rotated clockwise, it travels down toward the tip of the brace, spreading the rear edges of the pivoting jaws and closing the front edges by moving them inward. The cupped ends of the jaws are equipped with two rotatable hemispheres whose flat surfaces are bisected by a series of grooves cut to different widths. To adjust for different bit shanks, the floating hemispheres are rotated until the proper-sized groove faces forward. Since the hemispheres float, as well as rotate, both round and tapered shanks are accommodated.

The chuck requires a bit of fiddling to get a bit to center properly, and it needs to be well-lubricated if tapered bits are used. The brace pictured here is unmarked.

Amidon's Eclipse Ratchet Brace (1887)

The drawing of the Eclipse ratchet brace is courtesy page 113 of The Industries of Buffalo: a Resumé of the Mercantile and Manufacturing Progress of the Queen of the Lakes published by the Elstner Publishing Company in 1887. Available with an 8, 10, 12, or 14-inch sweep, the Eclipse brace featured a ratchet with pick-out pawls and a chuck with a retaining pin for holding its jaws in place. The image of the ratchet in locked position comes from page 54 of the March 1887 issue of the magazine Carpentry and Building. The detail of the unlocked Eclipse ratchet is taken from page 174 of the August 1888 issue of the same magazine.

Amidon's 2nd Improved Barber Chuck (1888)

In 1888, Amidon & Bastedo introduced a reworked version of Amidon's pioneering Barber Improved chuck. The original patent, held by the Millers Falls Company, had expired, so there was little to stop them from doing so. Hoping to build on the name recognition of the earlier product, Amidon & Bastedo referred to the design as "Amidon's 2nd Improved Barber chuck."

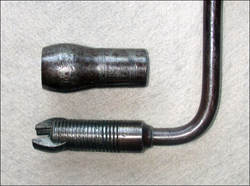

The chuck featured a thicker-than-usual sleeve and jaws designed to be held in the socket by a steel pin. The jaws themselves are similar to those on the original Barber Improved chuck save for a slot cast into them that allows for the passage of the retaining pin. The inside of the socket is deep and rectangular in shape to accept the jaws—unlike the round-bottomed cavity of the typical Barber Improved chuck. The rear of one of the chuck's jaws features a small pin that fits into a hole on the rear of the opposing jaw, an arrangement that guards against their getting out of alignment.

The company fitted Amidon's 2nd Improved Barber chuck to both simple and ratcheting braces. The illustrations seen here appeared on page 174 of the August 1888 issue of the trade magazine Carpentry and Building. The detailed photos of the chuck were sent to me by Stan Morgan in 2013.