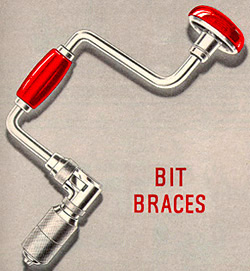

Millers Falls Bit Braces

In 1915, the company published Millers Falls Tools Catalogue No. 35. Within its pages were one hundred thirty-five variations on the hand brace—an astounding figure when you consider the basic simplicity of the tool. By 1938, however, the number of braces in the catalog had shrunk to thirty-five. In 1949, that number was reduced yet again, to thirteen.

In 1915, the company published Millers Falls Tools Catalogue No. 35. Within its pages were one hundred thirty-five variations on the hand brace—an astounding figure when you consider the basic simplicity of the tool. By 1938, however, the number of braces in the catalog had shrunk to thirty-five. In 1949, that number was reduced yet again, to thirteen.

The growing preference for electric boring tools was making itself felt in the workplace, and it is plain that the market could no longer sustain a huge line of braces, many of them differing only slightly from another. It is ironic, then, to consider that the braces being offered by American companies at this time were among the finest hand-powered boring devices ever mass produced. A good argument could be made that the Millers Falls line of premium braces was among the finest of that golden era.

The braces of the 1930s would have been a dream come true for a woodworker a century earlier. In the early nineteenth century, most braces were made of wood and prone to breakage if too much torque was applied to them. The forged iron braces sometimes made by blacksmiths were better in this regard, but both types were plagued with mechanisms inadequate to hold a bit securely and incapable of adjustment for variations in the size or shape of a shank.

One hundred years later, a brace with an adjustable Barber chuck, mounted on a quality steel frame and fitted with a rotating sweep handle and ball bearing head was considered bottom of the line. Better models came equipped with a ratchet mechanism allowing the user to bore a hole without making a full rotation of the sweep. Some of the best braces were manufactured with all or part of the ratchet mechanism enclosed, or “boxed.” Premium models came equipped with chucks which allowed for bits with a variety of shanks to be used. Fit and finish, of course, played a role in determining the eventual cost of the tool.

In addition to coverage of the company's standard bit braces, this section of the website includes information on its angular bit stocks, drill braces, and sill borers.