Featured: Early Breast Drills

No. 10 (mid-1880s)

In production by 1881, the No. 10 was a small breast drill only fourteen inches in length. A full 2 1/2 inches shorter than the earlier No. 12, it was one of three drills introduced about this time with a frame constructed of a single steel rod. With its gilt-edged, jet black drive gear and red breast plate, the drill was one of the several tools that marked the introduction of the red and black color scheme that was to characterize many of the

company's products. The company would wait until 1925 to register the combination as a trademark described as the “coloring of a distinctive part of each tool red and the main body or frame black.”

In production by 1881, the No. 10 was a small breast drill only fourteen inches in length. A full 2 1/2 inches shorter than the earlier No. 12, it was one of three drills introduced about this time with a frame constructed of a single steel rod. With its gilt-edged, jet black drive gear and red breast plate, the drill was one of the several tools that marked the introduction of the red and black color scheme that was to characterize many of the

company's products. The company would wait until 1925 to register the combination as a trademark described as the “coloring of a distinctive part of each tool red and the main body or frame black.”

Early No. 10 breast drills featured a crank that was cast as part of the main gear—a trait that it shared with its companion drill, the No. 11. The drills also shared a mechanism that allowed a worker to shift speeds without removing the main gear—a feature unusual at the time. The main gear is attached to a sliding side handle assembly, and a lengthwise slot is cut into the rod that comprises the frame. The gear is held in place by a thumb screw, and a small key that travels up and down the slot prevents the handle assembly from rotating on the shaft. To change speeds, the user simply loosens the thumbscrew, repositions the gear and tightens the thumb screw back down again.

Photo by author.

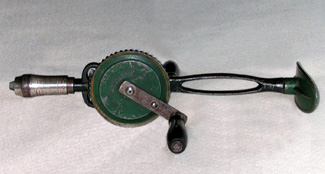

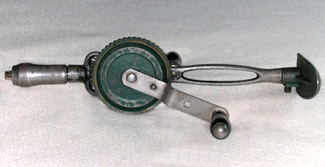

No. 10 (late 1880s)

The No. 10 breast drill was given a makeover around 1888. The timing and sequence of the changes is hard to determine since the company was loathe to update the plates used to print its catalogs. The drill seen here differs from that of 1884 in several ways.

The No. 10 breast drill was given a makeover around 1888. The timing and sequence of the changes is hard to determine since the company was loathe to update the plates used to print its catalogs. The drill seen here differs from that of 1884 in several ways.

The most obvious change is in the composition of its crank. Once cast in place as part of the main gear, it is now fabricated from thick sheet stock. Harder to spot is the addition of Goodell's secondary grip. The secondary grip, a change in the way the socket of the chuck was attached to the spindle, was designed to improve the jaws' ability to handle round-shanked bits. This example is equipped with Amidon's jaws.

This drill is fitted with a longer and heavier breast plate than that on the earlier model No. 10 seen above. This improvement likely pre-dates the addition of the Goodell grip. The main gear is decorated with a second gilt ring; earlier models were trimmed only on the outer edge. Interestingly, the back side of the large gear is sports a gilt circle just inside the row of teeth.

Photo by author.

No. 12 (mid-1870s)

The two-speed No. 12 breast drill was introduced to the market in 1873. The change in speeds was effected by re-positioning the drive gear on the frame, a procedure that allowed a second set of teeth on the gear to engage the pinion. An easily removed U-shaped pin, which engages a slot cut into the gear shaft, holds the drive gear in place when the drill is in use. Although the drive gears of the early No. 12s were painted green, color alone is a poor indicator of a drill's age as the Millers Falls Company used green tones on its cast frame models until the early 1920s. The earliest No. 12 drills can be distinguished by two features: a drive gear with a flat, unmachined outer surface and handles manufactured of domestic, rather than tropical, hardwood.

The two-speed No. 12 breast drill was introduced to the market in 1873. The change in speeds was effected by re-positioning the drive gear on the frame, a procedure that allowed a second set of teeth on the gear to engage the pinion. An easily removed U-shaped pin, which engages a slot cut into the gear shaft, holds the drive gear in place when the drill is in use. Although the drive gears of the early No. 12s were painted green, color alone is a poor indicator of a drill's age as the Millers Falls Company used green tones on its cast frame models until the early 1920s. The earliest No. 12 drills can be distinguished by two features: a drive gear with a flat, unmachined outer surface and handles manufactured of domestic, rather than tropical, hardwood.

Above right is a photo of the earliest No. 12 in my collection. It was manufactured about 1875, and features an unusual chuck patented by Albert D. Goodell on July 29, 1873. Goodell, a Millers Falls Company employee, developed the chuck with the idea of making a bit holder more flexible than the Barber Improved Chuck that served as standard equipment on the bulk of the company's boring tools. Certainly, the most innovative feature of the chuck was Goodell's use of a bow-spring with two loosely attached jaws. The arrangement adapted itself quite well to a variety of shanks. The patent was Goodell's second for a chuck and was assigned to the Millers Falls Company at the time of issue. There are two variations of the chuck: the cylindrical model with a cone-shaped tip seen above and a contoured model externally similar to the company's Barber Improved Chuck.

The patent papers for the 1873 chuck refer to the device as an “improvement to bit-stocks.” The description has created an expectation that the chuck would be found on bit braces, leading many to believe that it was never manufactured. (A further complication for researchers is that of the company's mis-stamping the chuck shell and crank with a patent date of June 10, 1873.) Despite its apparent flexibility, the Goodell chuck never caught on, and it soon disappeared from the company's offerings. Ironically, the company would use a similar set of bow-spring jaws for its universal chucks in the 1950s and 60s.

Photo by author.

No. 12 (mid-1880s)

By the time of the 1884 catalog, the Millers Falls Company was referring to its two-speed, malleable iron frame breast drill as the No. 12. The illustration of the drill and its accompanying text show that a number of changes had been made since its introduction. Certainly the most significant was the abandonment of Goodell's chuck and its replacement with the company's 'tried and true' Barber Improved Chuck. The reason for the change is not clear, although it may have been a matter of simple economics—Goodell's chuck would have cost more to produce. Then too, its less-than-substantial bow spring and unattached, easily lost jaws may have been a source of customer dissatisfaction.

By the time of the 1884 catalog, the Millers Falls Company was referring to its two-speed, malleable iron frame breast drill as the No. 12. The illustration of the drill and its accompanying text show that a number of changes had been made since its introduction. Certainly the most significant was the abandonment of Goodell's chuck and its replacement with the company's 'tried and true' Barber Improved Chuck. The reason for the change is not clear, although it may have been a matter of simple economics—Goodell's chuck would have cost more to produce. Then too, its less-than-substantial bow spring and unattached, easily lost jaws may have been a source of customer dissatisfaction.

Another early change, basically cosmetic, involved the replacement of the drill's domestic hardwood handles with rosewood. Somewhat later, the breast plate was re-designed. While still not adjustable, it was beefed up with a slightly heavier casting and lengthened by a half inch. The heavier breast plate may have been introduced to reduce the risk of breakage. The writer has seen several of the older drills with broken breast plates—most likely the result of a drop to the floor.

One of the more obvious changes that took place at about this time is harder to date. The company began to machine the outer surface of the drive gear in order to give the drill a more finished appearance. Although the change almost certainly took place prior to 1885, the No. 12 breast drill depicted in the catalog for that year is positioned with its back side to the viewer—effectively obscuring any details of the outer side of the drive gear. A gold stripe was added to edge of the machined side of the now-contoured drive gear—a decorative detail that remained part of the No. 12 for another forty years.

Photo by author.

No. 12: early 1890s

In 1887, the Millers Falls Company began fitting its No. 12 breast drills with Goodell's secondary grip. Rather than spend the money to update the illustrations in the company catalog, the company simply added text noting that the drill was equipped with the new grip. The improvement was designed to improve the drill's ability to grasp round-shanked bits by bringing extra pressure to bear on the back side of the jaws of the chuck. The chuck of the drill seen here is stamped with the date of Goodell's December 13, 1887 patent. It features the self-opening jaws patented by William H. McCoy, indicating that its manufacture postdates 1890.

In 1887, the Millers Falls Company began fitting its No. 12 breast drills with Goodell's secondary grip. Rather than spend the money to update the illustrations in the company catalog, the company simply added text noting that the drill was equipped with the new grip. The improvement was designed to improve the drill's ability to grasp round-shanked bits by bringing extra pressure to bear on the back side of the jaws of the chuck. The chuck of the drill seen here is stamped with the date of Goodell's December 13, 1887 patent. It features the self-opening jaws patented by William H. McCoy, indicating that its manufacture postdates 1890.

The drill includes a number of other improvements not present in the No. 12 drills of the mid-80s. Its crank is now offset, providing additional clearance for a worker's hand when rotating the drive gear. Its handle is now attached with a bolt rather than peened into place. Although cheaper to produce, the older-style peened handles were more difficult to install and harder for a customer to replace.

Photo by author.

No. 12: mid-1890s

The drill at right dates from the early-to-mid 1890s. The dull appearance of its exposed metal surfaces is the unfortunate result of a dip in an amateur restorationist's electrolysis tank. Be that as it may, the tool is illustrative of a host of improvements that the Millers Falls Company made to the No. 12 breast drill between 1885 and 1895.

The drill at right dates from the early-to-mid 1890s. The dull appearance of its exposed metal surfaces is the unfortunate result of a dip in an amateur restorationist's electrolysis tank. Be that as it may, the tool is illustrative of a host of improvements that the Millers Falls Company made to the No. 12 breast drill between 1885 and 1895.

The chuck of the drill is marked with a patent date of December 13, 1887. Although the date refers to the patent for Goodell's secondary grip, it does not incorporate his design. Manufactured at a time when the company was beginning to use ball bearings between chuck sockets and drill frames, the drill was fitted with an older chuck shell stamped with an obsolete date. The drill bears one other patent date—January 21, 1890—stamped on a small level mounted on the side opposite that seen in the illustration. The date refers to Letters Patent No. 419,703 issued to Joseph McLaughlin of Erving, Massachusetts, for a spirit level for bit braces. Although McLaughlin's design was for a level embedded in the head of a standard bit brace, the Millers Falls Company had no qualms about stretching the parameters of the patent to include the fairly mundane application of a small level to the frame of a breast drill.

The drill includes a number of improvements not present in earlier versions. Its breast plate, attached with a small locking screw, can be rotated on the frame, allowing the user to adjust it for comfortable use in a variety of situations. A thumbscrew, rather than an easily lost u-shaped pin, controls drive gear speed adjustment, and an idler roll is mounted to the frame to improve drive gear tracking. The drill seen here was among the last of the No. 12s to have its side handle positioned between the large gear and breast plate. By 1896, the company had repositioned it to a location between the chuck and drive gear.

Photo by author.

No. 13: mid-1880s

The No. 13 breast drill, introduced in 1881, featured a rod-type frame and was notable for a drive gear that was six inches in diameter. The oversized driver provided for a gear ratio of 4 1/2 to 1 and resulted in a tool especially useful for high speed drilling in thick metal. The company's only single-speed breast drill at the time of its introduction, the No. 13 was anything but cheap. Equipped with double pinions that provided extra stability for its drive gear, the heavily plated No. 13 sold for fifty percent more than the Millers Falls Company's two-speed No. 12. The firm made no bones about the cost of the tool. The 1887 catalog proudly noted that the No. 13 was “really the most expensive Breast Drill in the market.”

The No. 13 breast drill, introduced in 1881, featured a rod-type frame and was notable for a drive gear that was six inches in diameter. The oversized driver provided for a gear ratio of 4 1/2 to 1 and resulted in a tool especially useful for high speed drilling in thick metal. The company's only single-speed breast drill at the time of its introduction, the No. 13 was anything but cheap. Equipped with double pinions that provided extra stability for its drive gear, the heavily plated No. 13 sold for fifty percent more than the Millers Falls Company's two-speed No. 12. The firm made no bones about the cost of the tool. The 1887 catalog proudly noted that the No. 13 was “really the most expensive Breast Drill in the market.”

The drill seen at right was manufactured about 1885 and save for its crank retains most of its nickel plating. The degree of the company's interest in presenting the consumer with a high-grade tool is evidenced by the fact that even the unpainted top surface of its breast plate was also nickeled. Although only traces of the two gilt stripes that once decorated its drive gear have survived, it remains apparent to even a causal observer that the drill would have been a looker in its day. An example of the No. 13's earliest production, it features Charles Amidon's Barber Improved chuck—a design a decade and a half older than the drill itself.

Not long after this No. 13 was manufactured, the company replaced the drill's Barber Improved Chuck with a secondary grip patented by Albert Goodell in 1887. The company changed the design of the auxiliary side handle at about the same time. The side handle, not visible in the illustration above, was originally treaded onto an extension of the shaft supporting the drive gear. This arrangement was abandoned about 1887 when the auxiliary handle was offset and mounted an inch above the gear shaft. The No. 13 breast drill was manufactured until 1935.

Photo by author.