Irwin Auger Bit Company, the Early Years

Origins of the Solid Center Bit

While the Irwin Auger Bit Company liked to take credit for the invention of the solid center auger bit, the honor for the design belongs to George Shetter of York, Pennsylvania, who patented a single-spiral, single-lip version in 1829 and improved on it in 1831 by adding a second spiral and cutting lip. It is not surprising that officials issuing the patent for the Irwin bit overlooked Shetter’s earlier inventions. A fire at the United States Patent Office in 1836 destroyed most of the early records. As piecemeal as the historical record is, enough fragmentary and corroborative evidence remains to document Shetter’s accomplishment.(1)

While the Irwin Auger Bit Company liked to take credit for the invention of the solid center auger bit, the honor for the design belongs to George Shetter of York, Pennsylvania, who patented a single-spiral, single-lip version in 1829 and improved on it in 1831 by adding a second spiral and cutting lip. It is not surprising that officials issuing the patent for the Irwin bit overlooked Shetter’s earlier inventions. A fire at the United States Patent Office in 1836 destroyed most of the early records. As piecemeal as the historical record is, enough fragmentary and corroborative evidence remains to document Shetter’s accomplishment.(1)

Shetter was forty-six at the time of his first auger bit patent and well-experienced in forge work. A wagon smith earlier in his career, he operated a business that made cannon carriages for the federal government during the War of 1812. His rural Pennsylvania wagonworks were anything but modest; a contemporary drawing depicts a seven-forge manufactory employing at least two dozen men.(2) Shetter is listed as an auger maker in 1838 York County tax records and the 1850 Federal Census. Despite his long career as a bit maker, examples of his work remain difficult to find. A solid center, 1831 patented Shetter T-auger recently sold at auction(3) in Ephrata, Pennsylvania, not far from his hometown of York.

The man who came up with the idea for the Irwin version of the solid center auger profited little by his efforts. Lewis C. Achor, a carpenter living in Green Township, Clinton County, Ohio, is credited with developing the original wooden model and drawings for the bit.(4) A Civil War veteran, Achor had served with the 48th Ohio Volunteer Infantry, a unit that lost one-third of its active members in the Battle of Shiloh. A disability discharge ended his military career shortly afterward, and Achor returned to Green Township and returned to his trade. He came up with the idea for a solid center auger bit in the early 1880s and took his model and drawings to William M. Demitt, a local blacksmith.(5) Achor asked him to make a working version of the auger. At this point, for reasons unknown, Achor’s involvement with the solid center auger bit ceased.

Whether Demitt paid him for his idea or simply expropriated it, Achor missed an opportunity that would have made him well-to-do. He did, however, enjoy the consolation an exceptionally long life. Lewis C. Achor forswore chewing tobacco at age ninety-nine and lived to be one hundred.(6)

William Demitt was shrewd enough to understand Achor’s design had promise, made some changes to it, and applied for a patent. What happened next has become a matter of legend. One version holds that Demitt, a man with “a powerful taste for whiskey” and a liquor debt, traded the rights to Martinsville druggist Charles H. Irwin to satisfy a twenty-dollar account. A more common narrative is that Demitt had already patented his design and traded it to Charles H. Irwin, a saloonkeeper, to settle his bill.(7) The facts are not quite as colorful. Irwin operated a Martinsville drugstore, and though he may have sold patent medicines, his business certainly did not include a tavern.

On October 21, 1884, the United States Patent Office awarded William Demitt Letters Patent No. 306,907 for his auger. (Spelled Dimitt, in the document.) Though tradition has it that Lewis Achor’s original wooden prototype accompanied Demitt’s application, the award makes no mention of a model, an omission unusual enough to cast doubt on the story. The inventor assigned the rights to one-half of the patent to Charles Irwin. The druggist’s involvement suggests Demitt had taken a partner to share the cost of patenting his invention. Though documents detailing the partners’ arrangement on domestic sales have not been located, their agreement on foreign distribution has survived. Demmit assigned one-half the foreign rights to Irwin in exchange for one-half of the expenses of securing patents outside the United States.(8)

When Charles Irwin established a company to produce the auger bit the following year, William M. Demitt played no significant role in the organization. Perhaps the best explanation for Demitt’s absence is that he couldn’t make payment on his share of the patent costs and handed over his remaining rights to Irwin to settle the matter. Most certainly he did not trade his interest in the auger bit for a saloon. The origins of the colorful tavern story may lie in the 1888 purchase of Charles Irwin’s Martinsville property by Dimmit’s wife for $1,800. In doing so, she assumed Irwin’s $150 mortgage.(9) At the price, the transaction was hardly a sweetheart deal and certainly no trade to settle a debt.

The property may have been deeded to Mrs. Demitt because her husband was not good with money. Williams Demitt’s obituary in the April 8, 1918, Wilmington Daily News noted: “Demmitt was recognized as a genius in many ways but never rose higher than a repairman of unusual skill, and his business never grew to large proportions in that field because of his habits of life.” Given the evidence, it’s safe to conclude that William Demitt was no businessman.

Founding the Irwin Auger Bit Company

In the summer of 1885, Irwin traveled to nearby Wilmington, Ohio to look for individuals willing to invest in the auger bit. He persuaded three local men and a Washington, D. C. lawyer with Wilmington connections to form a business named the Irwin Auger Bit Company. Incorporated on October 1, 1885, the fledgling enterprise enjoyed a capitalization of $10,000.

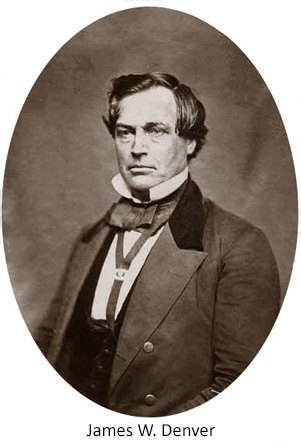

The Washington lawyer, James W. Denver, became the company's first president. A colorful man with an interesting past, Denver once fought in the Mexican-American War as a captain under General Winfield Scott. When hostilities ceased, Denver settled in California where he killed a newspaper editor in a duel, an incident that did little to harm his budding career. He went on to serve as United States Congressman, Governor of the Kansas Territory, Commissioner of Indian Affairs, and as a general in the Union Army. While governor of the Kansas Territory, he appointed the first permanent officers of Arapaho County in what is now the state of Colorado. His appointees returned the favor by naming the future city of Denver after him.

The Washington lawyer, James W. Denver, became the company's first president. A colorful man with an interesting past, Denver once fought in the Mexican-American War as a captain under General Winfield Scott. When hostilities ceased, Denver settled in California where he killed a newspaper editor in a duel, an incident that did little to harm his budding career. He went on to serve as United States Congressman, Governor of the Kansas Territory, Commissioner of Indian Affairs, and as a general in the Union Army. While governor of the Kansas Territory, he appointed the first permanent officers of Arapaho County in what is now the state of Colorado. His appointees returned the favor by naming the future city of Denver after him.

Peter C. Clevenger and Albert I. Bailey, the Irwin Auger bit Company’s founding vice-president and treasurer, were experienced businessmen who served as officers of Wilmington’s Champion Iron Bridge Company, a thriving bridge builder on its way to national recognition. Samuel J. Jones, the fourth of Irwin’s investors, remained a silent partner who held no office in the business. Irwin became Secretary of the Board of Directors and general manager. He received a one-cent royalty on each auger bit sold.(10)

At a meeting of the Champion Bridge Company directors on November 7, 1885, those present agreed to lease a portion of the bridge company’s property to the Irwin Auger Bit Company for the purpose of erecting a building suitable to contain the company’s operation for “one to three years.” The board also agreed to sell a portion of its power to the auger bit operation for $2.50 each day that the Champion Bridge Company was in operation and $3.50 per day when the Bridge Company was shut down.(11)

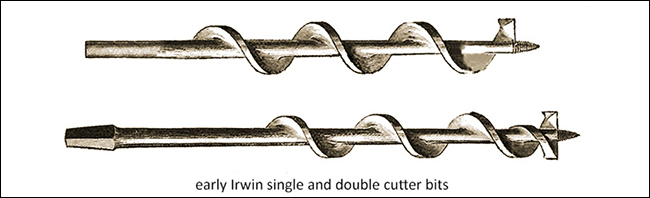

The Demitt patent covered a solid center bit with a single cutter. On October 14, 1885—two weeks after the organization of the Irwin Auger Bit Company—Charles Irwin applied for a patent on a double-cutter version of the solid center auger bit. Irwin’s design involved the addition of a short second spiral to accommodate the extra cutter. Once again, his idea had been anticipated by George Shetter, the Pennsylvania inventor whose single-cutter, solid center auger bit preceded William Demitt’s patent. Shetter had patented a solid center, double-cutter auger in 1831, and Irwin’s design added almost nothing to it. Both designs featured a short additional spiral at the cutting end to allow for the second cutting edge. Already working on his double-cutter bit while negotiations for forming the Irwin Auger Bit Company were taking place, Charles Irwin understood the necessity of getting a version into production if the company were to prosper. Most workmen used double-cutter augers as a matter of course, and a double-cutter head coupled with the strength inherent in a solid center bit would make for an attractive alternative.

Early illustrations of the Irwin auger on the company's billheads depict scotch-lip augers without spurs. If the illustrations are accurate, the bits represented by them must have been manufactured for only a short period. Surviving single cutter bits feature what is known as a double spur, a term confusing to many since it refers not to a pair of spurs but to a spur that extends both above and below the floor of a cutter. If the illustrations on billheads are to be believed, early double-cutter Irwin auger bits were equipped with scotch lips as well. If so, they were soon replaced with a pair of extension lips similar to those pioneered by Russell Jennings.

The process of turning William Demitt’s design into a marketable product did not go smoothly. A year and a half passed before the fledgling operation with its four employees and single trip hammer produced an acceptable product. The Irwin Company's Ohio location was a long way from the auger-bit manufacturing centers of the East Coast. Recognizing they were short on expertise, the company’s officers addressed the problem by importing five experienced auger-bit workers from New England.(12) One of these was William C. Johnson of Seymour, Connecticut, who filed a patent application for the dies to make Irwin's solid center bits on December 20, 1886. The Patent Office made the award on March 15, 1887, a short three months later. Charles Irwin must have been green with envy. Though the patent for his solid center, double-cutter auger was published the following month, it had taken the Patent Office a year and a half to complete the process. The Irwin Auger Bit Company appointed William C. Johnson plant supervisor on June 14, 1887, at a salary of 1,050 dollars. Under his direction, the company placed its first bit on the market in August.(13)

On October 15, 1887, Charles Irwin applied for a patent for a heading die to forge the cutting end of his auger bits. On the same day, he and Francis Thomas of Cincinnati applied for protection for a set of dies to be used after the heading die had done its work. These dies refined the roughly shaped cutter created by Irwin's heading die. William C. Johnson's name appears nowhere in the documents. It may be that Johnson's term as plant supervisor had already ended. Irwin succeeded him as Plant Superintendent, shedding the title of General Manager and moving closer to production.(14)

By spring of 1888, Irwin Auger Bit had grown from four employees to thirty and from a single trip hammer to three. Though it turned out augers by the wheelbarrow full, the operation had a backlog of 150 orders. Four traveling salesmen, and occasionally agents of the Champion Bridge Company, marketed its products. The April 12, 1888, issue of the Clinton County Democrat noted: "George W. Owens of the Champion Bridge Company returned Saturday evening from a few days' trip through Kentucky and Tennessee during which he sold two large bridges and $361 worth of Irwin Auger bits."

Though production reached a thousand bits per day in September, the company still had trouble keeping up with orders. A fourth trip hammer was installed in the forge room and a state-of-the-art heading machine ordered. The new equipment gave the plant the capacity to turn out two thousand bits a day. The Irwin Auger Bit Company had become a force to be reckoned with.(15)

The earliest Irwin auger bits are marked:

CHARLES H. IRWIN

PAT’D. OCT. - 21 - 84

IMP’D. APR. - 19 - 87

The Bailey Auger Bit

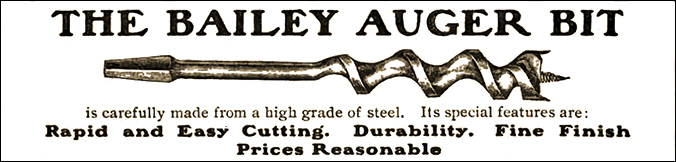

Competition came from an unexpected source in February 1889 when Josiah Bailey, the father of Irwin Auger Bit treasurer Albert I. Bailey, applied for a patent on a single-spiral auger bit. For reasons unknown, he chose not to license it to the company where his son was an officer. Though the development must have prompted considerable discussion among the other board members, there is no evidence indicating it affected Albert Bailey's business relationships. A prosperous man with a number of financial interests, Albert I. Bailey’s position as a major investor and treasurer of both the Champion Iron Bridge Company and Irwin Auger Bit ensured he’d suffer no fallout from his father Josiah’s activities.

The elder Bailey’s auger featured a single spiral for most of its length, and a short second spiral at the working end allowed for a second cutter and spur. Thinner on its outer edge than its inner, the gradually undulating spiral came as close as possible to having a solid center without infringing on Irwin's patent. The patent award, dated October 22, 1889, includes Bailey's claim that the thinner, outer edge of the spiral reduced friction between the bit and the wall of the hole. Bailey also maintained his design promoted the freer passage of large chips throughout the spiral's length.(16)

Josiah Bailey stamped his bits on the stem with a single line of text:

BAILEY BIT, PAT. OCT. 22, 1889

Whatever Albert Bailey's reaction to his father's patent, indications are Charles Irwin was less than pleased. A group led by Irwin filed for a patent on the dies Josiah Bailey needed to forge his bit just six months after Bailey applied for protection of his design. Irwin's co-developers included company employees J. W. Simmons and Francis I. Hoefle, who served as Irwin Auger Bit's die sinker and the forge room foreman.(17)

Lawyers were soon involved, and in late 1889, charges and countercharges appeared on the pages of the Scientific American, the Wilmington Journal, and the Clinton County Democrat. When Josiah Bailey's lawyers maintained no one could manufacture the new auger except Bailey himself, Charles Irwin had a ready answer.

... the dies for my own bits were patented by William C. Johnson, of Connecticut, in 1887, and of whom I had to purchase them before I could manufacture my own bits. It is only a reasonable assumption that Mr. Bailey will have to purchase my dies before he can use them for the forging of his bits. I have no intention of trying to manufacture Mr. Bailey's bit, an erroneous impression his attorneys seem to labor under. In my opinion such an undertaking would be a waste of time and money.(18)

The legal wrangling did nothing to slow the formation of the Bailey Auger Bit Company. Its officers had already found a suitable location for the business on the south side of Lancaster Ohio, a town of 7,500 some seventy-five miles from Wilmington. Josiah Bailey took up temporary residence there. His son-in-law, William A. Starbuck, served as president of the company. Like the Baileys, he was a devout Quaker and active in his local meeting. Josiah Bailey took his religion just as seriously. In the years leading up to the Civil War, he was an active participant in the abolitionist movement and in later life, became an ardent supporter of the temperance cause.(18)

The outcome of the Irwin/Bailey tussle remains unclear but in May 1891, Albert O. Spring, a Lancaster man affiliated with the Bailey Auger Bit Company, applied for a patent for a new set of dies that could be used to manufacture Bailey's bit. Convinced that Spring's dies were unique, the United States Patent Office rewarded his effort with a patent on May 26, 1891. Spring assigned the rights to the Bailey Auger Bit Company.(20)

By 1891 the officers of the Bailey Auger Bit Company had moved production of Josiah Bailey's auger to Harriman, Tennessee, home of the Harriman Manufacturing Company. Harriman, Tennessee had just been founded as a reformist temperance town, and Harriman Manufacturing was established to lure businesses to the area by providing startup capital. Although the relocation must have appealed to Starbuck and Bailey’s Quaker principles, the move proved disastrous. The Panic of 1893 bankrupted the land corporation that founded both the town and Harriman Manufacturing. The insolvency of the manufacturing company resulted in the bankruptcy of Bailey Auger Bit. When the smoke cleared, the manufacture of the Bailey bit remained in Harriman but under the auspices of a new entity, the Southern Auger Bit Works.(21)

By 1891 the officers of the Bailey Auger Bit Company had moved production of Josiah Bailey's auger to Harriman, Tennessee, home of the Harriman Manufacturing Company. Harriman, Tennessee had just been founded as a reformist temperance town, and Harriman Manufacturing was established to lure businesses to the area by providing startup capital. Although the relocation must have appealed to Starbuck and Bailey’s Quaker principles, the move proved disastrous. The Panic of 1893 bankrupted the land corporation that founded both the town and Harriman Manufacturing. The insolvency of the manufacturing company resulted in the bankruptcy of Bailey Auger Bit. When the smoke cleared, the manufacture of the Bailey bit remained in Harriman but under the auspices of a new entity, the Southern Auger Bit Works.(21)

The solution proved short-lived. By 1899, the rights to the Bailey Auger bit had passed on to the Ohio Tool Company. Bailey’s pattern became Ohio Tool’s signature auger. The company offered its standard Bailey carpenters' bits with either fine or coarse screws. Bits with fine screws featured extension lips. The coarse-screw version, designed for use in tropical hardwood, was spurless. Wanting to cover all the bases, the company manufactured a double spur Bailey bit in an effort to appeal to traditionalists.

Ohio Tool packaged its sets of bits in cloth rolls and generic American case boxes. The American case utilized individual spring-type clips wood-screwed to a transverse bar to hold bits in place. It was not patented. Often lined with red or black paper, boxes of varying quality and wood types are seen. A casual survey indicates the Ohio Tool Company had a preference for red interiors. The source of the company's American cases is unknown.

The Ohio Tool Company proudly marked the stems of its Bailey bits with a seven-line stamp.

ESTAB'D 1823

OHIO TOOL CO

BAILEY BIT

PAT. OCT. 22,

1889

HIGH GRADE

STEEL

The Bailey Auger Bit Company and Ohio Tool were not the only companies to produce the Bailey bit. A mysterious entity, the R. T. Company (location, and dates of operation unknown) also manufactured the bit, perhaps taking on production after the Ohio Tool Company plant flooded in 1914. The R. T. Company used a five-line stamp on the stems of its bits:

BAILEY BIT

PAT OCT. 22,

1889

R. T. CO.

WARRANTED

Irwin’s Role in Product Development

The extent of Charles H. Irwin’s participation in the design and development of the Irwin Auger Bit Company’s products is hard to determine. Between 1888 and 1891, Irwin played a role in an additional six successful patent applications. Four of them list him either as assignee or co-patentee. With no experience in engineering or mechanics, his involvement may have been as much on the business as on the design side. Since it was not unusual for nineteenth-century plant managers to secure rights to an employee’s design and then file for a patent, it is hard to determine the extent of Irwin’s contributions—even those listing him as sole inventor. Two 1888 patents covered the dies used to manufacture the company’s solid center auger bits. They were more defensive than innovative.(22)

The extent of Charles H. Irwin’s participation in the design and development of the Irwin Auger Bit Company’s products is hard to determine. Between 1888 and 1891, Irwin played a role in an additional six successful patent applications. Four of them list him either as assignee or co-patentee. With no experience in engineering or mechanics, his involvement may have been as much on the business as on the design side. Since it was not unusual for nineteenth-century plant managers to secure rights to an employee’s design and then file for a patent, it is hard to determine the extent of Irwin’s contributions—even those listing him as sole inventor. Two 1888 patents covered the dies used to manufacture the company’s solid center auger bits. They were more defensive than innovative.(22)

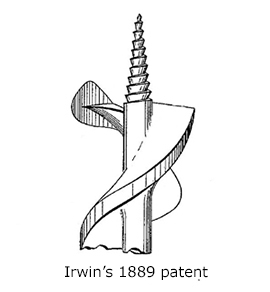

On May 28, 1889, the United States Patent Office issued Irwin yet another patent for a solid center auger bit. The award document lists no other co-developers or assignees. In it, Irwin referred to the design as an improvement of his double cutter bit of 1887. Unlike the earlier design, the second cutter of the new bit did not feature a spur, and its cutting edges were staggered rather than directly opposite each other. Irwin claimed the arrangement would “to steady the bit in its operation.” It is not known if the Irwin Auger Bit Company manufactured the bit in the patent drawing, but it would market an auger bit with a similar cutting head as the “Surebor” some thirty years later.

That fall, Charles Irwin acquired a share in the rights to a patent seemingly unrelated to his work at the auger bit company. United States Letters Patent No. 411,541 protected the design of a heater box invented by two of Irwin’s former Martinsville neighbors: Tobias Hamilton and Lewis Achor, the blacksmith with the original idea for Irwin’s 1884 version of the solid center auger bit. When in place, the Hamilton/Achor box captured heat that normally escapes through a chimney for reuse in cooking or heating an upper-story apartment. While it is doubtful Irwin planned to manufacture the heater at the auger bit company, he may have hoped to capitalize on the design by selling it to the Farquhar Furnace Company, a profitable manufacturer of heating devices headquartered in Wilmington.

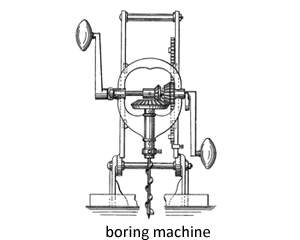

Irwin closed out 1889 by completing a patent application for an improved boring machine, a collaboration with Irwin Auger Bit employees John E. Hitch, the foreman of the packing room, and Friederich Mill. The machine’s design allowed for easy speed changes when changing from large to small bits. The Patent Office issued the award document on May 6, 1890. (23)

A few years earlier, the Irwin Auger Bit Company had served as sole agent for a product known as The Boss Machine, a boring machine patented in 1882 and manufactured in Indiana. A notice in the May 10, 1888 issue of the Wilmington County Democrat indicates the company leveraged the arrangement to create crossover sales of its auger bits.

A notice in the 1890 Christmas Day issue of The Iron Age refers to the Irwin Company’s auger, car, machine, and boring machine bits. It makes no mention of boring machines, and an examination of contemporary trade literature provides no evidence that Irwin Auger Bit ever manufactured the device. John E. Hitch’s work on the boring machine marked the beginning of a foray into product development. He would go on to patent another three designs for the company—all as sole applicant.

On June 17, 1890, Charles Irwin and employee Francis I. Hoeffle patented a single-spiral auger bit vaguely reminiscent of Josiah Bailey’s design a year earlier. The patent documents allow for a short second spiral to accommodate an additional spur and cutter as well.(24) The new auger went nowhere, but the patent marked the end of Irwin’s active involvement in getting legal protection for the company’s products. In the months following the patent award, a devastating bout of influenza during the second wave of the Russian flu pandemic damaged his health severely, forcing him to reduce his participation in the day-to-day operations of the company.

On June 17, 1890, Charles Irwin and employee Francis I. Hoeffle patented a single-spiral auger bit vaguely reminiscent of Josiah Bailey’s design a year earlier. The patent documents allow for a short second spiral to accommodate an additional spur and cutter as well.(24) The new auger went nowhere, but the patent marked the end of Irwin’s active involvement in getting legal protection for the company’s products. In the months following the patent award, a devastating bout of influenza during the second wave of the Russian flu pandemic damaged his health severely, forcing him to reduce his participation in the day-to-day operations of the company.

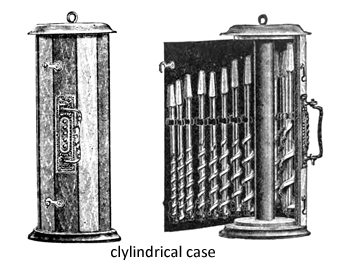

Hitch's cylindrical case

Irwin’s declining health did not prevent his boring machine collaborator John E. Hitch from patenting a cylindrical auger-bit sample case in 1891. A spool with a hardwood top and bottom, Hitch’s case featured a center post to which a cloth roll backed with wooden slats was attached.

Irwin Auger bit advertised and distributed the cases prior to the 1892 publication of the patent. Though the company promoted the container as a “convenient and durable case for the mechanic as well as ready seller for the dealer,” it had been designed for countertop display. Complex and fragile, Hitch’s case proved impractical for day-to-day use. The thin metal fittings holding the augers to the cloth roll were inadequate to hold them firmly in place. The bits were easily dislodged and prone to tumbling to the floor. A less-than-careful opening of the case created a jumble and a time-consuming return of the bits to their original positions. Shipped at no additional cost with the purchase of a set of 32 ½ quarters (the standard set of 13 bits). Hitch’s case was not offered as a stand-alone item.(25)

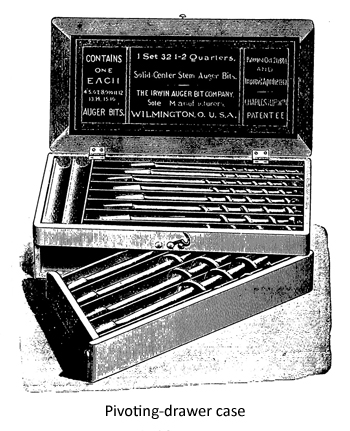

The pivoting-drawer model case

The problems with the Hitch bit case led to its quick demise. By the end of 1892, the company had introduced what it referred to as its “model case.” A rectangular box with a hinged lid, the model case featured an individual trough for each bit. A fixed upper tray provided storage for the smaller augers and a pivoting lower drawer for housing the larger ones.

The problems with the Hitch bit case led to its quick demise. By the end of 1892, the company had introduced what it referred to as its “model case.” A rectangular box with a hinged lid, the model case featured an individual trough for each bit. A fixed upper tray provided storage for the smaller augers and a pivoting lower drawer for housing the larger ones.

Since the bits in the lower drawer were longer than those in the upper part of the box, the company added several crosswise short troughs to the upper tray to keep the bits residing there from sliding back and forth. Running at a ninety-degree angle to the rest of the slots, the short troughs were left empty, allowing a customer to store such odds and ends in them as desired. A century later, the empty short troughs would provide tool collectors with fodder for much speculation about the nature of their original contents. Irwin Auger Bit distributed the pivoting drawer model case for various combinations of bits until 1933.

Irwin takes his leave

By 1892, the now-successful company Charles Irwin and his co-founders established had grown to employ 55 male workers and four juveniles.(26) Though Irwin Auger Bit was doing well, Irwin was not. His bout with the flu had severely damaged his lungs, leaving him a semi-invalid. Believing he would not survive another Ohio winter, Irwin moved to Texas. He returned to Wilmington in 1893 to settle his affairs. The Wilmington Daily News-Journal provides a succinct account of what transpired.(27)

On August 3, 1893, Irwin offered to sell 90 shares of Auger Bit stock at the door of the Clinton County Courthouse. These shares represented 20 per cent of all the company’s stock. . . . The Depression of ‘93 was in full swing about that time and the first block of ten was sold to C. Ed. Merker for $56 a share. The remaining shares were quickly withdrawn from the market.

On August 9, General Denver, an Irwin backer died. Irwin on leaving for Asheville, N. C., told his associates that his doctors gave him one chance in 10 to live and he was going to take that chance. But the odds were too great, and he died in Asheville on Sept. 2, 1893, with his mother at his side. He was buried in Greenfield with 40 Irwin employees in attendance.

. . . A bachelor, Irwin was quiet and shy but showed a remarkable talent for business matters. His only living relative was his mother who lived on a farm near Greenfield.

Surprisingly, for the organizer of a successful company bearing his name, information on Charles Irwin is hard to come by. Unmarried and childless, he left no immediate family interested in preserving his memory. A contemporary obituary or a photo of him has yet to surface.

Illustration credits

- Reconstructed drawing from United States Letters Patent X6428 for George Shetter auger made in conformity with the Patent Act of 1837.

- C. H. Irwin drugstore: Courtesy Ed Farrell.

- James W. Denver portrait: courtesy Wikipedia, original by Whitehurst Studio ca. 1856.

- Early Irwin bits: edited image from 1889 billhead.

- Bailey auger bit ad: edited image from Hardware Dealers Magazine, 1905.

- Box of Bailey bits manufactured by Ohio Tool Company: Author's photo.

- Drawings of 1889 cutting head and 1890 boring machine: edited drawings from patent documents.

- Cylinder case: Iron Age, October 15, 1891.

- Pivoting-drawer case: Carpentry and Building, December 1892.

References

- Price, James E. “On the History of the Solid Center Auger Bit.” Chronicle of the Early American Industries Association, v. 44, no. 2, (June 1991), p. 35; Price, James E. “George Shetter, Father of the Solid Center Auger.” Chronicle of the Early American Industries Association, v. 46, no. 1, (March 1993), p. 20.

- York, Francis. “Book Offers Some Biographical Background on George Shetter.” The Gristmill: Published for the Members of the Mid-West Tool Collector’s Association. no. 79, (June 1995), p. 13.

- George Shetter (York, Pennsylvania) T-handle auger, patent dated 3/21/1831. The Voices of Experience Antique Tool Auction. Horst Auction Center: Ephrata, Pennsylvania, January 20, 2016.

- “Patentee of Irwin Auger Bit Dies in Obscurity Last Week in Westboro.” Wilmington Daily News (Wilmington, Ohio), April 18, 1918. p. 6; “Sister of Originator of Auger Bit, Practically Blind, Spends Tedious Hours Fashioning Rugs.” Daily News-Journal (Wilmington, Ohio), August 15, 1929. p. 10.

- Also spelled “Demmitt,” “Demitt,” "Dimmitt," and “Dimit.”

- "Ohioan Celebrates His 100th Birthday." Toledo Blade (Toledo, Ohio). July 25, 1941. p. 7.

- “Irwin Made Its Mark Bit by Bit.” Dayton Daily News (Dayton, Ohio). August 10, 1997. p. 31-32; “Patentee of Irwin Auger Bit Dies … .” Wilmington Daily News (Wilmington, Ohio), April 18, 1918. p. 6.

- Clinton County Ohio. Office of the Recorder. Agreement Book 2. p. 279.

- Clinton County Ohio. Office of the Recorder. Deed Book 43. p. 105.

- “The Irwin Auger Bit Company.” Wilmington Journal (Wilmington, Ohio). May 23, 1888. p. 1; Burritt M. Hiatt. “Then and Now: Birth of the Irwin Auger Bit Co.” Wilmington Daily News-Journal (Wilmington, Ohio). February 23, 1960. p. 16.

- David H. Miars. A Century of Bridges: the History of the Champion Bridge Company and the Development of Industrial Manufacturing in Wilmington, Ohio. Wilmington, Ohio: Cox Printing Company, 1972. p. 16.

- “Business Briefs.” Wilmington Daily News-Journal (Wilmington, Ohio). April 21, 1961. p. 9.

- Irwin's Patent: United States Letters Patent No. 361,522; Johnson's Patent: United States Letters Patent No. 359,313; “Wilmington’s Largest Industry Completes 65 Years of Growth.” Wilmington Daily News-Journal (Wilmington, Ohio). October 2, 1950. p. 2.

- United States Letters Patent No. 413,159; United States Letters Patent No. 453,052; "Former Days". Wilmington Daily News (Wilmington, Ohio). September 7, 1918. p. 2.

- "Capacity of Auger Works Being Doubled." Clinton County Democrat (Wilmington, Ohio). September 27, 1888. p. 3.

- United States Letters Patent No. 413,159.

- United States Letters Patent No. 412,957.

- "A Statement from Mr. C. H. Irwin." Clinton County Democrat (Wilmington, Ohio). November 28, 1889. p. 3.

- "A New Enterprise at Lancaster." The Commerical Gazette (Cincinnati, Ohio) November 22, 1889. p. 1; Untitled notice. Miami Helmet (Piqua, Ohio), December 12, 1889. p. 2.

- United States Letters Patent No. 453,052.

- “The Southern Auger Bit Works.” Iron Age. April 5, 1894. p. 676.

- United States Letters Patent No. 378,251; United States Letters Patent No. 378,408.

- United States Letters Patent No. 427,325.

- United States Letters Patent No. 430,344.

- “Free to All Purchasers.” Iron Age. April 5, 1891. p. 95.

- Ninth Annual Report of the Ohio Department of Inspection of Workshops, Factories, and Public Buildings … Columbus, Ohio : The Department, 1892.

- “Birth of the Auger Bit Company.” Wilmington Daily News-Journal (Wilmington, Ohio). February 23, 1960. p. 16.