Millers Falls Braces 50 through 134

Much of this listing has been developed from information found in Millers Falls catalogs. The features listed for each brace may differ from actual examples. While the company typically stressed new features in its catalogs, it seldom mentioned the disappearance of a feature or a feature that had become so commonly accepted that it was no longer noteworthy. Then too, production practices varied from catalog copy and illustrations were slow to be updated. By 1960, catalog copy had become so vague that a detailed description of features is not possible.

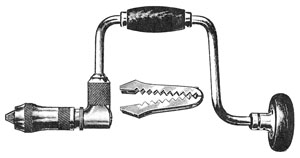

No. 50 (chain drill)

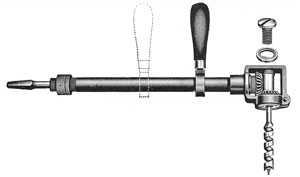

Combination Ratchet Brace and Chain Drill

Combination Ratchet Brace and Chain Drill

- 1905 — fully boxed ratchet; cocobolo head and handle; ball bearing head; brass rings in wrist handle to prevent splitting; nickel plating; spring-type alligator jaws. Includes chain.

- 1910 — as above, but wrist handle rides on adjustable bearings; Master Chuck with Leland's universal jaws.

- 1912 — as above, but catalog notes that the unit includes four feet of chain.

The No. 50 featured a removable chuck. The chuck could be removed, a chain drill attachment substituted, and the chuck then inserted into the chain drill attachment. Also included was a simple bushing-type socket, with a square opening, that could be substituted for the chuck.

The popularity of individually sold chain drill attachments doomed the No. 50. Although less elegant in that most of them required the use of two chucks (one to hold the chain drill attachment and another the bit), they were easily inserted into any number of braces.

Illustration from 1905 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 50 | 12 inch | 1905 | 1914 |

Nos. 50 - 54 (Barber)

- Lignum vitae head; rosewood wrist handle; brass rings in wrist handle prevent splitting; Barber's jaws with Stevens' sleeve.

Unwilling to commission new art work, the Millers Falls Company used an outdated woodcut dating from the early 1870s to represent this brace in its catalogs until at least 1887. The illustration bore no resemblance to the actual tool.

Note: An example of a No. 53 marked The Stoughton Brace has been reported by Jerry Davis. The designation is stamped on the shell of the chuck. Edward P. Stoughton worked as sales manager for the firm's New York office and later became company president. His role in the development or marketing of the brace is unclear. A rubbing of the mark and a photo of the brace have been provided courtesy of Jerry Davis. The patent date seen on the rubbing is that for William Barber's chuck. Other examples of the Stoughton brace have turned up since the Davis report.

Author's photo of ca. 1880 brace.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 50 | 14 inch | 1885 | 1890 |

| No. 51 | 12 inch | 1885 | 1890 |

| No. 52 | 10 inch | 1885 | 1890 |

| No. 53 | 8 inch | 1885 | 1890 |

| No. 54 | 6 inch | 1885 | 1890 |

No. 51

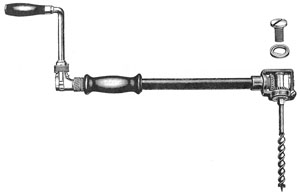

Malleable iron frame; hardened steel gears and bushings; ball bearings; adjustable hardwood handle; frame is japanned.

Often referred to as a joist tool. Used in conjunction with a bit brace or breast drill for boring at right angles in cramped quarters. Especially useful for car builders and electricians.

Illustration from 1915 catalog.

| Model No. | Length | Sweep | Start Date | End Date |

|---|---|---|---|---|

| No. 51 | 16 1/2 inches | n/a | 1913 | 1933 |

No. 52

Malleable iron frame; half-boxed ratchet; hardened steel gears and bushings; ball bearings; hardwood sleeve-type steadying handle; crank fitted with hardwood handle; frame is japanned.

Often referred to as a joist tool. Especially useful for car builders and electricians.

Illustration from 1915 catalog.

| Model No. | Length | Sweep | Start Date | End Date |

|---|---|---|---|---|

| No. 52 | 23 inches | 12 inches | 1914 | 1931 |

No. 54

Malleable iron frame; hardened steel gears and bushings; ball bearings; adjustable hardwood handle; frame is japanned.

Often referred to as a joist tool. Used in conjunction with a bit brace or breast drill for boring at right angles in cramped quarters. Especially useful for car builders and electricians.

Illustration from 1917 catalog.

| Model No. | Length | Sweep | Start Date | End Date |

|---|---|---|---|---|

| No. 54 | 16 1/2 inches | n/a | 1917 | 1933 |

Nos. 61 - 63

- 1879 — half-boxed ratchet; lignum vitae head; rosewood handle; brass rings in wrist handle to prevent splitting; nickel plating; Barber's jaws.

- 1880 — Stevens' sleeve added to Barber's jaws.

- 1894 — as above, but fully boxed ratchet, rosewood head rides on ball bearings; steel washer between ratchet and chuck sockets.

- 1901 — as above, but return to half-boxed ratchet.

- 1905 — as above, but cocobolo head and handle.

- 1914 — as above, but head and handle of tropical hardwood.

- 1917 — as above, but native hardwood head and handle.

Out of production 1881-ca.1884. Illustration from 1897 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 61 | 12 inch | 1879 | 1922 |

| No. 62 | 10 inch | 1879 | 1922 |

| No. 63 | 8 inch | 1879 | 1922 |

Nos. 71 - 73

Barber Improved Brace, non-ratcheting

Barber Improved Brace, non-ratcheting

- 1885 — hard maple head and handle; tumbled steel parts (not polished); Amidon’s jaws.

- 1897 — as above, but stained hardwood head and handle.

- 1905 — as above, but bar-and-slot jaws.

This is the non-ratcheting version of Nos. 82-83.

Illustration from 1905 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 71 | 12 inch | 1885 | 1912 |

| No. 72 | 10 inch | 1885 | 1912 |

| No. 73 | 8 inch | 1885 | 1912 |

Nos. 82 - 83

- 1885 — half-boxed ratchet; hard maple head and handle; tumbled steel parts (not polished); Amidon’s jaws.

- 1897 — as above, but stained hardwood head and handle.

- 1905 — as above, but bar-and-slot jaws.

This is the ratcheting version of Nos. 72-73.

Illustration from 1905 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 82 | 10 inch | 1885 | 1912 |

| No. 83 | 8 inch | 1885 | 1912 |

Nos. 92 - 93

Brace with thumb screw chuck, non-ratcheting

Brace with thumb screw chuck, non-ratcheting

Hardwood head and handle; equipped with Goodell’s self-cutting thumb screw; thumbscrew applies pressure on the corner of a square-shanked bit, rather than the flat.

Similar to No. 103 save for thumb screw patented by Albert D. Goodell on June 15, 1880. No examples with a Millers Falls or Amidon mark have been reported. May have been produced for the Millers Falls Company by the H. S. Bartholomew Company of Bristol, Connecticut.

Illustration from 1887 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 92 | 10 inch | 1885 | 1890 |

| No. 93 | 8 inch | 1885 | 1890 |

No. 97

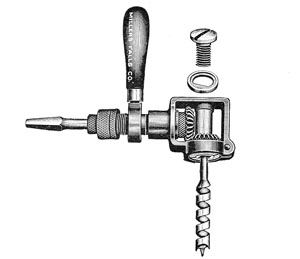

Barber Improved Ratchet Brace with adjustable sweep

Barber Improved Ratchet Brace with adjustable sweep

Fully boxed ratchet; Barber Improved chuck; thumbscrew adjustment of the handle allows for an 8, 10, or 12 inch sweep; nickel plated.

In addition to reducing the number of braces a workman might carry, the No. 97 can be disassembled and stored in a smaller space than needed for a standard brace.

Illustration from 1897 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 97 | 8-12 inches | 1897 | 1899 |

Nos. 102 - 103

Barber Improved Brace, non-ratcheting

Barber Improved Brace, non-ratcheting

Unstained hardwood head and handle; tumbled steel parts (not polished); bar-and-slot jaws.

This is the non-ratcheting version of nos. 202-203 was the bottom of the line in 1905.

Illustration from 1905 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 102 | 10 inch | 1905 | 1912 |

| No. 103 | 8 inch | 1905 | 1912 |

No. 103 (thumb screw)

Brace with thumb screw chuck, non-ratcheting

Brace with thumb screw chuck, non-ratcheting

Hardwood head and handle; equipped with a ‘plain’ thumb screw that applies pressure on the flat of a square-shanked bit.

The very bottom of the line in 1887, these braces cost 23 cents each when purchased in quantities of a dozen or more. No examples with a Millers Falls or Amidon mark have been reported. May have been produced for the Millers Falls Company by the H. S. Bartholomew Company of Bristol, Connecticut.

Illustration from 1887 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 103 | 8 inch | 1885 | 1890 |

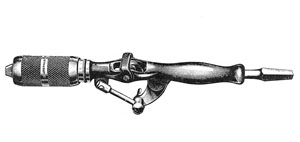

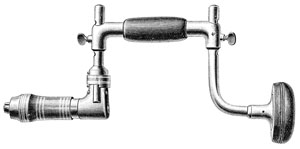

No. 108

- 1910 — single universal joint; rod-and-thumbscrew adjustment mechanism; main casting is japanned; bright parts are nickel plated; Master Chuck with Leland’s universal jaws.

- ca. 1922 — as above, but indexed adjustment mechanism consists of slotted overlapping pieces of sheet metal with pre-set stopping points and lockable thumb screw. Universal joint enameled red.

Used with bit brace or breast drill as an extension or angular borer. Many thanks to Svet Denkov for his observations on the history of this tool.

Illustration from 1915 catalog.

| Model No. | Length | Sweep | Start Date | End Date |

|---|---|---|---|---|

| No. 108 | 12 1/2 inches | n/a | 1910 | 1944 |

No. 109

Single universal joint; rod-and-thumbscrew adjustment mechanism; main casting is japanned; bright parts are nickel plated; Barber Improved chuck with spring-type alligator jaws.

Supersedes Anthoine's universal angular bit stock. Used with bit brace or breast drill as an extension or angular borer.

Illustration from 1915 catalog.

| Model No. | Length | Sweep | Start Date | End Date |

|---|---|---|---|---|

| No. 109 | 12 1/2 inches | n/a | 1897 | 1922 |

Nos. 117 - 119

Hardwood head and handle; Bartholomew’s jaws.

An inexpensive brace manufactured by the H. S. Bartholomew Company of Bristol, Connecticut, and sold by the Millers Falls Company. Features jaws patented by Harry. S. Bartholomew on May 24, 1870. Dates referenced in table apply only to those years the tool was sold by Millers Falls.

Illustration from 1884 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 117 | 8 inch | ca. 1878 | 1885 |

| No. 118 | 9 1/2 inch | ca. 1878 | 1885 |

| No. 119 | 10 1/2 inch | ca. 1878 | 1885 |

Nos. 120 - 124

- 1885 — half-boxed ratchet; ebonized hardwood head and handle; polished steel parts; no washer between frame and chuck socket; Amidon’s jaws.

- 1895 — steel washer between frame and chuck socket.

- 1896 — as above, but stained hardwood head and handle;

- 1905 — as above, but fully boxed ratchet; ball bearing head; spring-type alligator jaws.

- 1919 — as above, but wrist handle with inserted metal rings to prevent splitting, anti-friction washer in head.

This is the ratcheting version of Nos. 20-24, and was considered a mid-priced when introduced. It could be ordered with an octagonal chuck shell, 1912-ca. 1917.

Illustration from 1915 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 120 | 14 inch | 1912 | 1919 |

| No. 121 | 12 inch | 1905 | 1919 |

| No. 122 | 10 inch | 1885 | 1919 |

| No. 123 | 8 inch | 1885 | 1919 |

| No. 124 | 6 inch | 1915 | 1917 |

No. 129

Half-boxed ratchet; hardwood head and handle; Bartholomew’s jaws.

An inexpensive brace manufactured by the H. S. Bartholomew Company of Bristol, Connecticut, and sold by the Millers Falls Company. Save for ratchet, similar to Nos. 117-119. Dates referenced in table apply only to those years the tool was sold by Millers Falls.

Illustration from ca. 1885 Hibbard, Spencer, Bartlett and Company catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 129 | 10 1/2 inch | ca. 1881 | 1885 |

Nos. 130 - 134; 130A - 134A

(Model nos. designated ‘A’ were equipped with a steel clad, ball bearing head.)

- 1912 — concealed ratchet; cocobolo head and handle; ball bearing head; wrist handle rides on adjustable bearings and steel rings prevent splitting; nickel plated; spring-type alligator jaws.

- 1914 — as above, but head and handle of tropical hardwood.

- 1915 — as above, but wrist handle lacks adjustable bearings.

- 1917 — as above, but cocobolo head and handle.

Identical to Nos. 30-34 except for the concealed ratchet.

Illustration from 1915 catalog.

| Model No. | Sweep | Start Date | End Date |

|---|---|---|---|

| No. 130 | 14 inch | 1912 | 1935 |

| No. 130A | 14 inch | 1912 | 1919 |

| No. 131 | 12 inch | 1912 | 1935 |

| No. 131A | 12 inch | 1912 | 1919 |

| No. 132 | 10 inch | 1912 | 1935 |

| No. 132A | 10 inch | 1912 | 1919 |

| No. 133 | 8 inch | 1912 | 1935 |

| No. 133A | 8 inch | 1912 | 1919 |

| No. 134 | 6 inch | 1912 | 1915 |

| No. 134A | 6 inch | 1912 | 1915 |